Hi all, it has been a packed week and a half! Two days ago, we made a relatively unplanned stop in Boston Harbor after spending the previous week 400 miles offshore. The primary piece of equipment that the scientists are using to collect their data, an oil-filled acoustic array, THORA, went down a few days ago and they did not have the parts they needed to fix it onboard due to 4 packages that contained their troubleshooting equipment and spare parts being lost by the airline. We had to leave port without them at the beginning of the cruise due to time constraints, but they were found a few days ago. The Chief Scientist decided that getting the equipment onboard to fix the array was worth the two-day transit to pick it up, so we’ve spent the past 5 days primarily transiting from our study site to Boston and back.

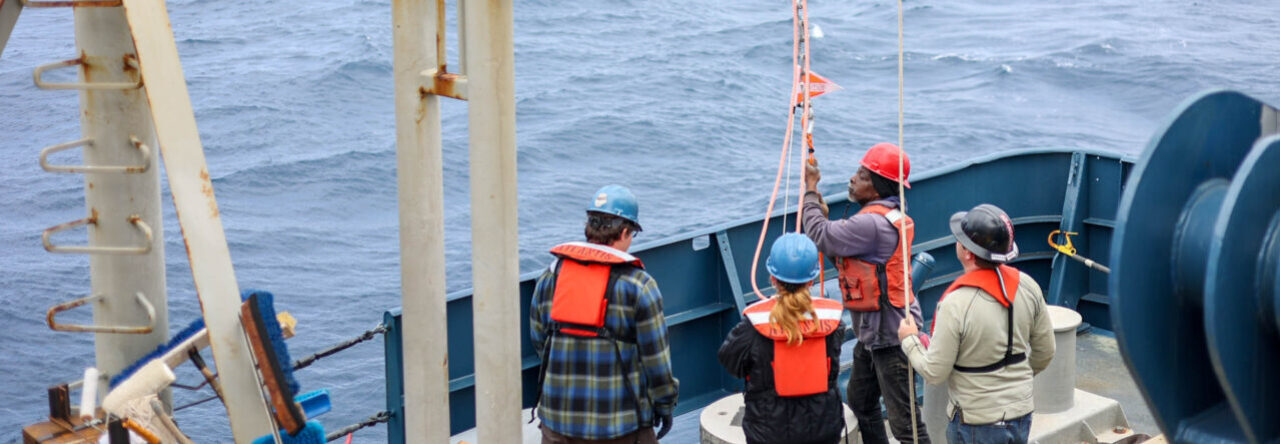

So far, we have done multiple CTD (conductivity, temperature, depth) and XBT (eXpendable BathyThermograph) deployments and a whole bunch of acoustic tow tracks. The acoustic array looks like a long, thick cable with a long, oil-filled tube attached to it that extends hundreds of feet in the water behind the ship. It listens for sounds in the surrounding water, including sound broadcasted from the R/V Roger Revelle, which has been operating acoustic research equipment in the area for the same project. The Revelle has been deploying an acoustic source, and the THORA array that we tow behind the ship has been listening for the sound emitted by the Revelle to understand how sound transmission through the water is affected by the Gulf Stream and the seamounts at our study site. CTDs and XBTs both give us a vertical profile of sound velocity in the ocean, since sound velocity is a factor of temperature and salinity.

When I first came onboard the ship, I expressed interest in gaining experience in troubleshooting science systems. Well, I’ve definitely gotten my fair share of it over the last week and a half. The CTD was giving us data transmission errors on one of our winches for almost all of the first week, with some of the errors corrupting an entire upcast and others just being small blips in the data. So, myself and the two full-time marine techs, Bonny and Jason, have spent a significant amount of time troubleshooting the source of the errors. The current list of things we’ve done to troubleshoot is nearly in the double-digits, but the CTD is now working error-free on our second winch and we are planning on testing it on winch 1 again soon!

We are currently towing the acoustic array behind the ship and doing coordinated operations with the R/V Revelle and deploying XBTs about every hour along our track. Later today, we will put the SeaTrac, an autonomous boat, in the water to collect additional acoustic data from an array that it tows beneath it. In my downtime while on shift, I’ve mostly been reading manuals for the various shipboard science systems, learning more about the computer networking systems onboard, helping out with regular maintenance tasks like cleaning and organizing, and various other tasks given to me by my mentors.

TTYL!

Armored THORA cable after a suspected shark attack. The science team suspects that the stress inflected on the cable during the attack may have partially caused the system to go down a few days later. Photo credit: Johnathan Todd.

THORA acoustic array being deployed.

Bosun Oscar securing the XBT launcher to the rail.

Myself (left) and my mentor Bonny (right) re-terminating the CTD cable as part of our troubleshooting efforts.

Bonny deploying a CTD at sunset.