Today makes 42 days on the R/V Thomas G. Thompson. As the monsoons close in and the winds pick up, it is safe to say it has been a complete and total whirlwind!

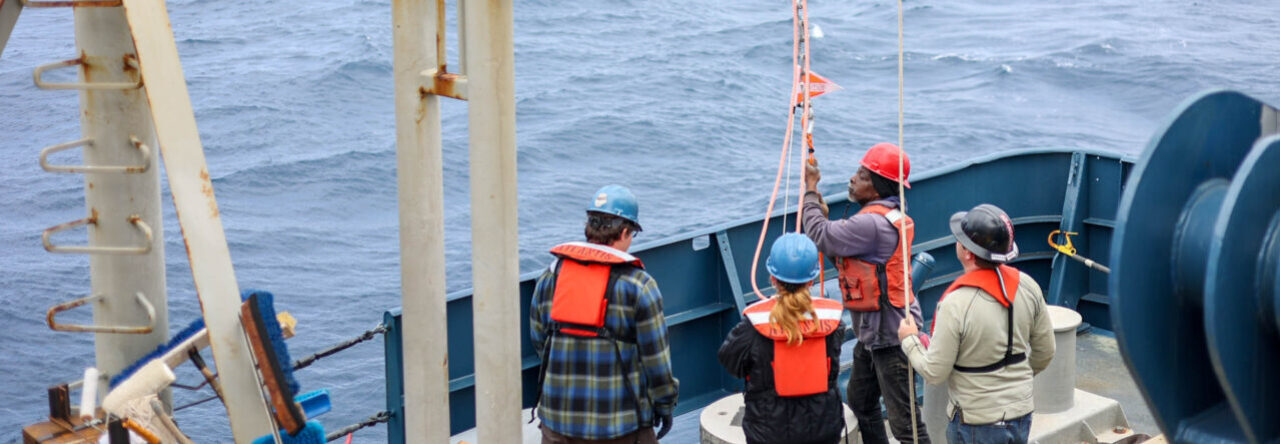

This research cruise is focused on gathering meteorological data. The use of weather balloons allows the science group to record various data through the atmosphere. The giant balloon is filled with helium, and attached to the bottom is a spool of wire with an instrument known as a Radiosonde. The instrument package measures atmospheric parameters such as pressure, temperature, humidity, wind speed, and wind direction. This information is sent back to the scientists via radio signals. Our highest balloon yet rose to 27.5 KM! The team releases a new balloon every few hours, for continuous data streams. I was able to release one as well!

As well as atmospheric data, the science group is interested in oceanographic profiles. This device, called a Scanfish, is towed behind the boat for days at a time. It swims up and down through the water column, and collects profiling data. Deploying the device means all hands on the stern, working to get it over the back smoothly.

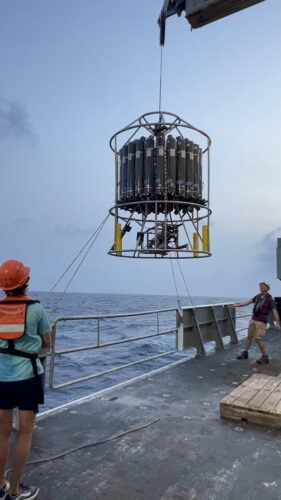

Another data source is the CTD. This is one of the most used pieces of equipment on board a research vessel! This science group is interested in water samples as well, so the large bottles you see will be full once we retrieve the device. The role of the marine technician in this deployment is mainly to operate the hydroboom, which is a horizontal crane of sorts. It can carry an enormous amount of weight, and carries the payload up to 10 feet off the side of the ship. The marine tech also communicates with the bridge and the winch operator, ensuring that the deployment goes smoothly. The scientists are responsible for the control of the CTD electronically, and triggering the bottles to close at whatever depths they want water samples from.

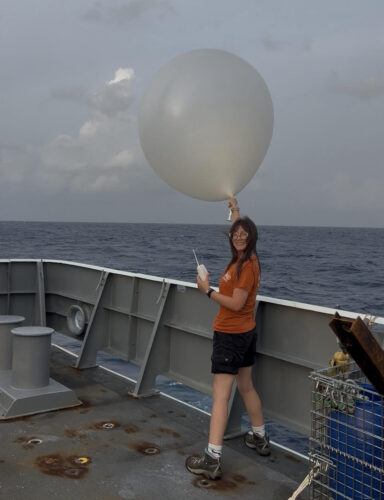

It has finally come time that the buoy on deck can be deployed! This specific buoy is experimental, meaning it is the first of its exact kind. The configuration of instruments is hopeful to provide insight into the air-sea interface, having both air and water sensors attached. This also means, however, that no one is sure exactly how the buoy will behave, or if it will be successful at all. Deployment was a slow, and very careful process. Once the buoy was in the water, all we could do was wait and see.

Our buoy has proven to be a bit cantankerous! After less than 24 hours in the water, the electrical systems onboard the buoy began to fail. The buoy is equipped with several large batteries that are charged by 3 solar panels, yet all charge had been lost. Either the solar panels were not functioning properly, or the equipment on board was too demanding for the batteries to keep up with. We decided it was the best option to recover the buoy, and see if repairs could be made on board. Every day spent at sea can be very expensive, so there is no time to waste. Science must go on!

The team was able to repair the electrical issues within the buoys system, and redeployed successfully. For several days, we received good data from the buoy with no signs of further electrical issues. In the meantime, we worked on other operations in the area. We continued to tow the Scan fish, with occasional stops for CTDs, and other data collection. Once it was time to revisit the buoy, disaster had struck. As soon as the buoy was in sight, we could see that the mast was broken. Sadly, there is no telling exactly how it happened, but the most likely culprit is simply weather conditions. The seas and winds have been very high, and the aluminium mast was under much stress. Trying to recover any equipment that is broken is unpredictable at best. The captain of the ship gathered the crew and scientists, and preformed a risk assessment of the potential recovery operation. With the uncertainty, and possible loose pieces that could come off at any point, there were concerns and discussions about the safety of such an operation. We were able to find solutions to our concerns, and decided that recovery was possible. We very slowly approached the buoy, and after two attempts and nearly 3 hours, were able to safely recover the equipment.

At sea, there are an infinite amount of problems and solutions you can encounter. It is important to keep an open mind and to think outside of the box when performing research! This week has proven to me that there are always work arounds and more chances to be had. Though the buoy is officially out of commission for this cruise, theres no doubt that it will float again, eventually. The beauty of an experiment such as this, is that it will only improve from here. The scientists now know the weak points, and how to improve it for its next deployment!

The rain here is picking up, so as we all don our foulies and our rain boots, we wish you luck on all of your endeavors! Stay safe and stay dry out there sailors.