Hello Readers!

As I write, it is currently day 6 into my MATE internship working with my mentor, the lovely Grace Fulton on the Pt. Sur, and let me tell you… I have been learning A LOT!

On my first day aboard the Pt. Sur, I had just flown in from Seattle that evening and met some of the crew and had dinner with Grace before heading to bed early. We went to bed early since we would begin mobilizing and working at 6 AM sharp the next day! We woke up nice and early to bring in the CTD, rollers, and tugger winch block, using the J-frame crane to bring them onto the deck. The CTD just came back from getting repaired, so Grace craned that and the tugger winch block onto the deck. I carried the rollers aboard, and man were they heavy! The rollers and the tugger winch block will be used for the DEEPEND project which uses a MOCNESS net.

.jpg)

The project uses a MOCNESS (Multiple Opening and Closing Net Environmental Sensing System) net that carries long big nets that are triggered on the boat so the net can be released any depth and time to capture whatever biology is in the water! This net takes up the entire deck and takes a team to deploy it and bring it back up.

I spent the rest of the day learning so many cool things! Me and Grace set up the CTD with various sensors, including me learning how to correctly identify ports and connect cables to the CTD so that the sensors can use the conductivity, salinity, and temperature parameters to work!

I was able to learn how to create a cable termination needed for the MOCNESS net winch to work and that included me learning how to use a rotary cutting machine to cut through many layers of metal cable. Cutting through that cable was hard since it was my first time and it honestly intimidated me but after many mistakes and redoing it, I got the hang of it. I then had to solder the winch cable and the cable a co-PI wanted to connect to the MOCNESS net and then used heat shrink to protect the new connection. To finish it off, I learned how to make a silicone mold of the terminator to fully protect the entire process I spent drilling off wire, soldering, and heat shrinking. Once that was nice and dry, we tested the connection, and it works perfectly!

On my second day we woke for our 6am-6pm shift and noticed that the flow-thru system was having trouble connecting to the computer in the technician lab, so we went to check out the flow-thru system and found that the power supply for the system was disconnected so there was zero power going to it. We plugged it back in and the problem resolved, PHEW!

Soon after, we went out on the deck to put the transducer pole in the water, and I went to unchain the pole from the side of the boat when my helmet fell off and it went under the boat. I learned my lesson and now tighten my helmet as hard as I can.

When we left the port, we began to have issues with the backup GPS system used to help with navigation and other instruments that needed it. The main issue with the GPS is the heading, what direction the front of the boat is pointing towards. We troubleshooted by resetting the system, but it did not work, so we started investigating the software and found that the GPS was on but not able to recognize satellites and therefore where forward was. We went ahead and emailed a person who created the software for the GPS and found that the issue could be with the cable, connection, or antenna. Troubleshooting for this issue has been hard, however the solution as of right now is using the gyrocompass which only gives heading direction!

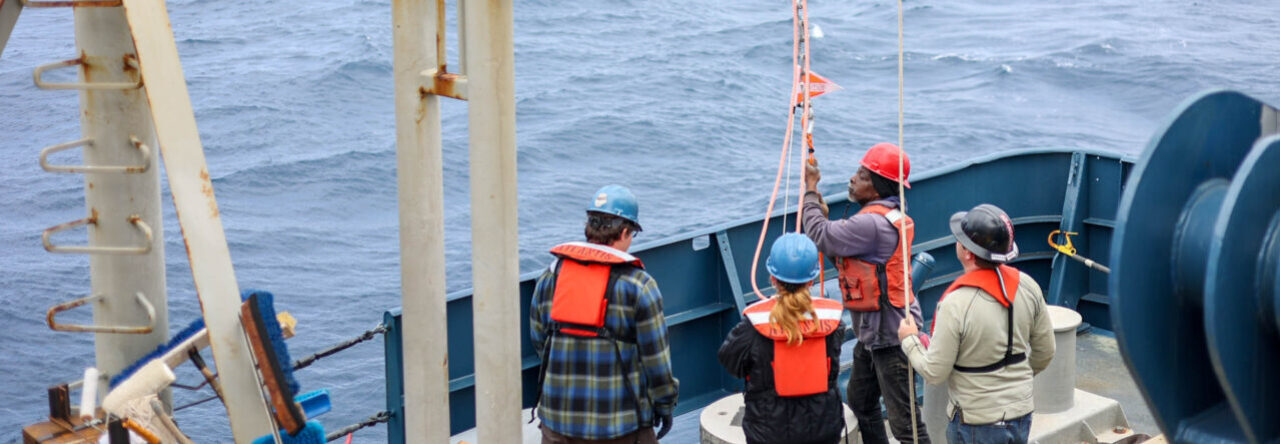

I also got to control different frames on deck! I got to use the A-frame which helps take out heavy equipment/instruments off the stern and I got to use it every time the MOCNESS net needs to deploy. Along with that, I got to use the J-frame which helps get the CTD on and off the starboard side of the ship! It’s simpler than I thought although it’s absolutely heavy and huge and I’m so happy I get the opportunity to handle these types of machinery!

On my third day on the ship, I got to learn how to tie the basic knots and a bunch of other useful knots I will be using a lot more on the next cruise. I finally solidified my bowline knot, and learned how to do different bowlines, different hitches, and a few knots! I have been practicing my knots every day and seem to get better at them the more I practice.

I also learned how to read and make hand signal while a crane is operating. For example, if I want the person operating the crane to move the crane up, I point my index finger up and make a circle motion to signal up. Along with the signals themselves, I have also learned to associate the terms with them like knuckling and boom up which I have a bit of trouble remembering, but with enough practice I’ll be set.

I also got my practice with Seasave, the software used for running, saving, and manipulating the data for the CTD. It was a bit daunting for me but having Grace guide me in every step of the way while I learned was super helpful and I can now say I am familiar and able to conduct a CTD cast on my own! I now know how to rerun previous CTD casts, for example, to note if our transmissometer is still malfunctioning and see which data is useful and which isn’t.

After that, things started to slow down as the boat was drifting since we deployed the MOCNESS net and that’s when I got the rundown of the Wi-Fi. The Wi-Fi on this ship is using Starlink and has a limit of 1TB every month. They had just upgraded the Wi-Fi just this year and is capable of fast Wi-Fi. This means that marine technicians have to keep a close eye on the Wi-Fi as they are in charge of it, at least on this research vessel, and have to make sure not to exceed the monthly internet limit. This means me and Grace have to keep watch on our daily limit and warn individual users not to use too much if we do start to notice an excess use of the internet.

On my fourth day, things started off pretty slow! Grace decided that to continue troubleshooting our transmissometer issue, I should replace the entire y-cable it is connected to that also connects to the fluorometer and that then runs to the CTD. I did just that and waited until a CTD cast was needed to test the cable out and the transmissometer was still malfunctioning. We will try to switch the y-cable inputs and see if it is the cable malfunctioning or if it truly is the transmissometer. If that doesn’t work then Grace thinks there is an issue with the pins on the transmissometer, the CTD pins, or the CTD itself. Not sure yet how we will test that, but it would be very rewarding to figure out once and for all what has been causing this issue for the entire cruise!

I learned a couple new knots, a sheet bend and a round turn and two-half hitches! The sheet bend was simple to learn but hard to remember. The round turn and two-half hitches knot were a bit hard for me to learn and harder to remember but after practicing a bunch, I think I can remember it! Grace has been helping me out with memorizing the knot names, tying knots, and their uses by quizzing me randomly throughout the day. I find this immensely helpful as daily practice will solidify my memorization and as she explained, if we are in some sort of emergency, I need to know how to tie certain knots to secure something or attach my line to another object.

Finally, I ended my shift by working the A-frame and J-frame all on my own! This means I got to recover the MOCNESS net using the A-frame all on my own. In my opinion, it was a bit bumpy using the A-frame on my own without guidance, but the recovery went super well! I also got to control the J-frame which moves the CTD in and out of the starboard deck. I got to deploy it using the J-frame which I have practiced a bunch the past few casts, and I got to recover it by grabbing ahold of the entire rosette and everything went smoothly! I’m proud of myself that I can be capable of so much equipment and instruments, and seeing as I have more to learn, I am so excited to see what else I am capable of!

I can’t wait to tell you all what else I will learn! Stay tuned and see you next week!

Kristine