Hello 🙂

The past week we have been doing many CTD casts. We did our deepest cast the other day that reached about 2800m. We colored some styrofoam cups and sent them down on the rosette to shrink; they were all very creative and turned out so nice. After each cast, we secure the deck unit and take water samples for the scientists. We first need to ensure the bottles did not leak and were properly closed when fired. At each collection depth, we fire two bottles in case one of them leaks. After we have all of our samples, we flood the floor by emptying the Nisking bottles. Then reattach the strings to the top and bottom to leave the bottles open for the next cast. The sensors are then covered with caps and the seawater pumps are flushed with DI water. They did an NSF livestream in which Lorelei and I are in the background of the video doing our CTD maintenance haha.

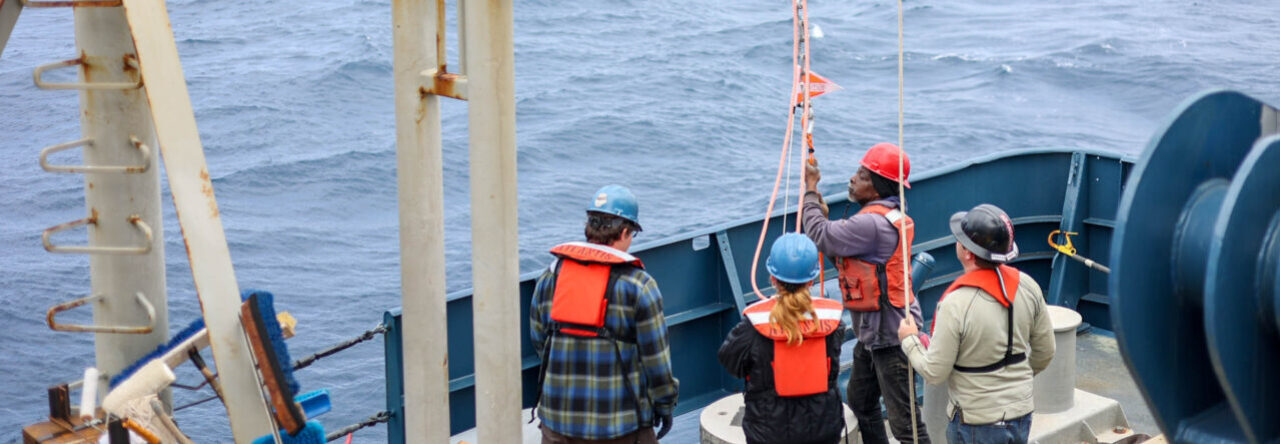

This week we have also done two mooring deployments. I soldered a new cable for Jim’s deck unit because he needed a five prong pin out as opposed to the three prong that was connected to the Knudsen. The Knudsen is a sub-bottom profiler that performs seismic profiling of the seafloor to indicate water depth below the ship. Jim’s deck unit allows him to send a ping to communicate with the acoustic releases on the bottom of the mooring cable. The moorings are a rather complicated set up because they are anchored at the seafloor and each device on the cable needs to float at certain depths. To set up the mooring correctly, there is a lot of communication going on between those on deck, those on the bridge, the winch operator, and the A frame operator. I learned about the hand signals used between the deck and operators, as well as safety procedures on deck. They had two successful mooring deployments but were not able to recover the older mooring because of the thick ice in the area.

We have also been conducting XCTD casts which are small expendable CTDs. They are released through a canister and connected to a copper wire that transmits depth, temperature, conductivity, and salinity information. For one of the casts I was on the radio communicating with the bridge and aft con. We need to ask for permission to stage the cast, give the serial numbers on the device, load the probe, aft con tells us we can launch, then we cut the wire once we reach the seafloor or terminal depth.

My 3D printing knowledge has also been expanded upon. The printer is capable of making really cool objects, but there are sometimes limitations based on the settings used before printing. I have learned to use supports and a brim to help the printer follow the correct path, stagger the seams for more strength, use alpha infill for an exposed roof so the part does not implode under pressure, and to minimize the size as much as possible so the print does not take too long. My fluorometer mount design is finally working and we will test it out on a CTD cast soon.

I have spent some time on the bridge/ upper decks to get a good view of the ice breaking. It’s pretty incredible to watch and I am impressed with the ship’s capabilities. I’m glad to be here and have definitely been enjoying my internship on the Healy.

Will post another update soon.

-Gabby