Hello for the last time from the R/V Langseth! As I am writing this, I am about 100 nautical miles from arriving at the island of Sao Vicente, part of the Cape Verde archipelago! While my time aboard the Langseth has been relatively short, it has been nothing short of an amazing and worthwhile experience that I would heavily recommend participating in should you have the opportunity!

Early in the week, Theo and I tackled revisions to the DigiBird calibration manual, making it more concise, structured, and user-friendly. We wanted future users to have a clearer, more streamlined guide, and we’re confident our updates will make troubleshooting much easier.

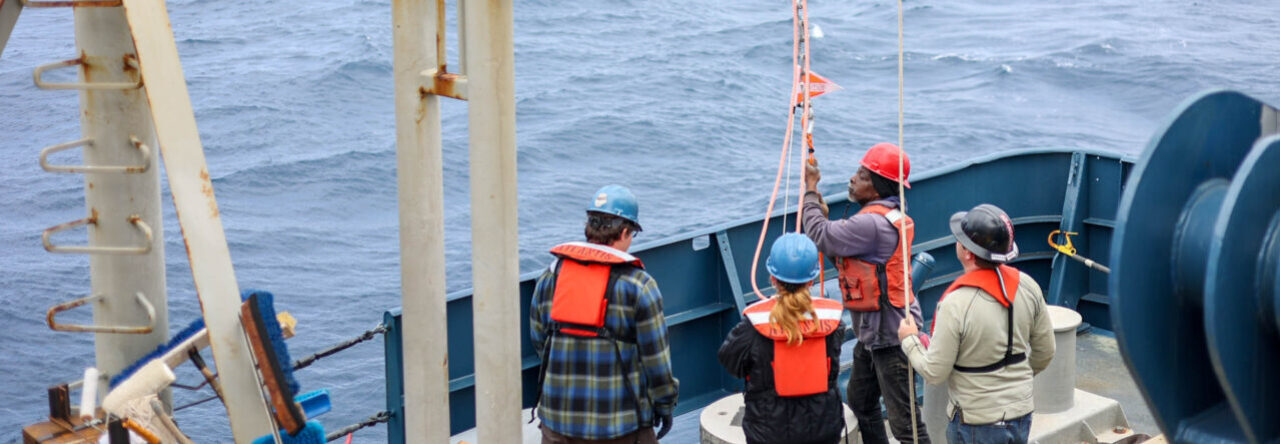

Midweek, we turned our attention to inventorying our equipment, unpacking and inspecting 56 old and new Niskin bottles for damage before organizing them into labeled palletainers. I also got my first experience calibrating Acoustic Pingers, which are much easier to work with compared to DigiBirds. Acoustic Pingers are an essential component of the Langseth’s streamer deployment, as they communicate with not only one another, but also the ship, relaying critical information as to where exactly the streamer currently is in the water. Working up in the protected species observer tower was a nice change of pace—removing and recalibrating Vaisala weather station antennas gave us a reason to soak up the fresh ocean air while still getting things done.

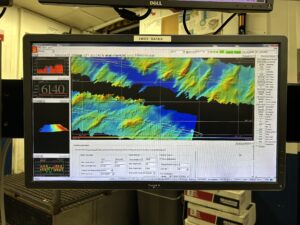

A major highlight of the week was learning about streamer deployment and seismic data acquisition. We unspooled a streamer on deck, attached LAUMs (Line Acquisition Unit Modules), and got hands-on experience using the SEAL 428 seismic recorder system. It was fascinating to see how hydrophone data is converted from analog to digital and how external noise sources, like fishing gear and passing ships, can interfere with data collection.

To end the week, Theo and I tackled the task of replacing the Digibird motor modules that were either bad or paired with bad electronic modules. Cody had recently taught us how to do so, so this allowed us to put his teaching into practice, which we did with great effectiveness! To replace a motor module requires essentially stripping the Digibird of all its interior components, requiring very cautious exactness and patience in order to ensure we do not damage any components during a motor swap.

We were able to complete either a motor swap or a complete haul of every component on every bird we aimed to, allowing us to finish our internship with a great sense of achievement and set the next set of interns up for success, as we tested all spare motors to find which were good and bad so they didnt have to! I can say for sure, I am adept in all things relating to the calibration and troubleshooting of Digibirds!

Thank you for keeping up with my weekly posts, it has been a pleasure sharing the amazing experience I have had. I also want to give a huge thank you to Chief Science Officer and my mentor, Cody Bahlau, for his dedication in seeing that Theo and I succeed, thrive, and take as much advantage of this opportunity as possible. And of course, a huge thank you to the UNOLS-MATE Program Manager Maria Osiadacz for making this opportunity possible and being such a wonderful support throughout the entire internship!

Wishing you the best,

Will