We’re finally closing in on Mindelo in Cabo Verde! We get in tomorrow morning at around 6am, and after that I am headed back to San Diego. This past month has flown by, and I’m super grateful to have had this opportunity—I feel like I have learned so much. I’m looking forward to staying in touch with the technical team and participating in similar opportunities down the line!

Now let me catch you up to speed on this past week. And when I say catch you up to speed, only one thing comes to mind: birgatory. We spent a lot of time working in the Bird Shack this week, and we started off pretty easy working on the Acoustic Pingers. These instruments are very similar to our digibirds except they’re a whole lot simpler: they basically just ping the boat to let us know the location of the streamers in the water behind us. All we had to do was recalibrate them and recharge their batteries. We were bumped up a level in difficulty, however, when we started working on the digibirds with bad motors. This took FOREVER. Let me walk you through testing one bird: you dismantle the bird, carefully dismantle and pull out the compass module, push out the motor and the electronics modules, carefully disconnect the motor from the electronics, carefully reconnect a new motor back to the electronics, reinsert both modules back in the bird, put the whole bird back together, and finally retest the motor functionality. If the bird still doesn’t work, you troubleshoot it by redoing that process all over again with a different motor. If both motors aren’t working, then the electronics module was bad, which meant stripping the bird for parts and retesting both the original and replacement motors. It was definitely hard work and ever-so-slightly mind numbing. At the end of the day, however, (and maybe because I never have to do it again) I can tell you that it was definitely a valuable learning experience for me. In any opportunity moving forward, I know I can calibrate, troubleshoot, and repair sensitive scientific equipment, even if I know very little about the instrument to begin with.

Speaking of sensitive equipment, perhaps the highlight of my week was getting the chance to run through troubleshooting our streamers. We finally got to test out one of the streamers on deck, unspooling the very end before screwing in a few LAUMs (line acquisition unit modules). Following that, we moved downstairs to learn how to read and interpret the data from the hydrophones, and how to troubleshoot the system if something goes wrong. It was super super interesting, and I would love to get more experience doing data analysis and troubleshooting in the Main Lab control room in the future. The program the Langseth team uses, SEAL, models all the data being transmitted from each individual hydrophone along the entire 15km line, as well as every LAUM and FDU (field digitizing unit). This amounts to five hundred something hydrophones for each streamer, half that many FDUs, and a couple dozen LAUMs. It’s pretty incredible technology and was great to experience so closely.

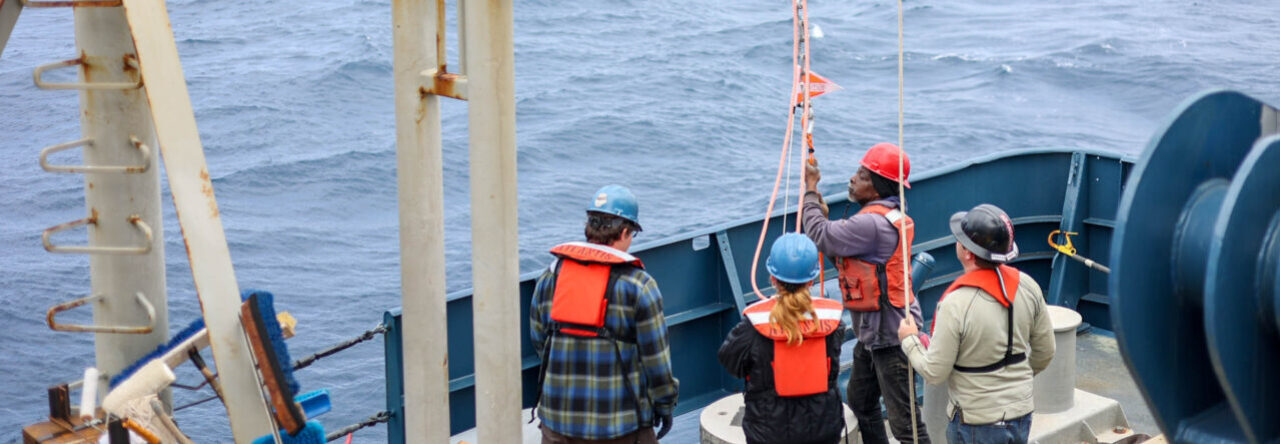

I’d say my final highlight of the week was working up on deck, familiarizing myself with Niskin Bottles and working on the Vaisala Weather stations. This scientific equipment aligns a lot more closely with my own personal interests in biological oceanography, and after a few weeks it was interesting taking a little break from seismology. While we didn’t actually get to apply either of these instruments, I did become pretty familiar with how to take them apart and put them back together again. If I’ve learned anything from this experience, understanding the fundamentals of how something works is a great substitute to deploying an instrument in the field. I know I got a lot more of the former than the latter over the course of this internship, but I am leaving feeling very confident in my ability to perform technical duties aboard a scientific vessel. Again, I am very grateful to have had this opportunity, and I look forward to applying the skills I learned over the course of this internship to future projects.