Hello 🙂

This week at sea I am learning how to be flexible and adapt to the changing environment. A few days ago, there was an electrical fire that caused a mission ending failure. This has taught me how quickly plans can change at sea, and how difficult it is for us to get the proper support we need all the way out in the Arctic. Luckily everyone is safe, and we are still able to reach about 12 knots to head back towards a port where the ship can be repaired. This unfortunate incident gave insight into the steps the engineers and damage control personnel need to take when dealing with emergency situations. When encountering an emergency, there are certain alarms that the ship will sound; it’s important to listen to these messages and muster when necessary to ensure everyone is safe and accounted for.

I got a tour of the engineering spaces, which was very fascinating to see the inner workings of the ship. I saw the huge generators & four diesel electric drive motors responsible for propulsion, the cycloconverters & transformers responsible for proper power distribution throughout the ship, the heat transfer systems used to cool off the motors, the desalination plant where the ship can make 6000 gallons of freshwater a day, the boiler room which sends steam to power the turbines plus other equipment, and other spaces responsible for running the ship. The Healy is considered the most “technologically advanced” icebreaker because of the variety of scientific equipment onboard and the ability to monitor oil, water, and voltage levels throughout the ship from a computer. Instead of getting down in the hard to reach places in the bilge, the engineers can monitor all systems and control where water, oil, and electricity are sent throughout the ship. I also got a tour of aloft con which is where the ice pilots steer the ship from when we are in 7/10 ice coverage. Aloft con is a few ladders above the bridge, and gives the officers a 360 degree view of the ship. From aloft con, they have a good view of the stern wake. When we are moving through ice, they can see where the ice has high pressure based on how the wake closes in as the ship moves through an area of dense ice coverage.This gives indication of how the rudders should be adjusted and how to maintain the safest track through the ice.

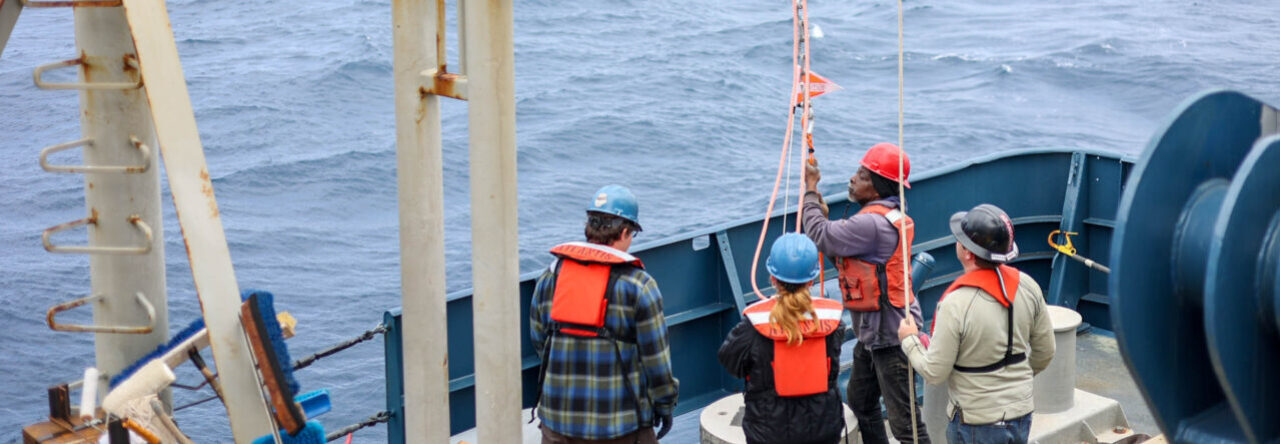

On the science side, we had to stop doing CTD casts because the new mission is to get the ship back to a reliable port safely. We did 24 hours of XBT (expendable bathythermograph) casts which we can do while we are moving. For safe measure, we typically ask the bridge to slow down to about 6 knots when doing these casts. We launched 1 XBT on the hour for 24 hours. The XBT collects sound velocity data by measuring temperature as it falls through the water column. I was on the radio in the computer lab for some casts and on deck for others. In the lab, I request permission from the bridge to stage the XBT launch. Then I tell those on deck that I am standing by for the probe serial number which I enter into the XBT launch program. Once the bridge and lab confirm the serial number, we tell the deck to load the probe and check for good communication with the device. Then the deck asks the bridge for permission to launch. In the lab, I check the multi-beam and if we are in over 1000m water depth, I wait until the probe reaches its terminal depth of 1000m to end the cast. If we are in shallower water, I wait until the probe reaches the bottom and then tell the deck they can cut the copper wire to finish the cast. After the wire is cut, I load the cast data in the sound-speed manager and edit it to delete the data from the surface before the probe hits the water. The water temperature profile is then sent to the multi-beam so the acoustic device can more accurately send and transmit signals to the seafloor. Some of the JOs (junior officers) were sent from the bridge to learn about what we are doing so I got to teach about the process too. They taught me a lot about their work schedules and the qualifications they need to earn to work certain positions. They taught me about the different Coast Guard ratings/ranks and career paths that each can pursue depending on their specialty.

I was also learning how to change the gain value, tx power, range, phase, and process shift on the Knudsen sonar device to get better depth readings. When we suddenly enter deep water or go from deep to very shallow, the acoustic range and phase need to be altered so that the Knudsen knows which depth to look at. Then the gain value should be decreased in shallow water to reduce the surface reverberation. In deep water, the gain value and tx power should be increased to send a signal that is strong enough to receive a return signal. I have learned how to identify multiples that can be caused by multiple harmonics. If there is one multiple, the signal has reflected off the seafloor and back to the surface twice, so the seafloor line can appear deeper. The multiples can be caused by seafloor sediment that is less porous and reflects the sound wave instead of absorbing. The multiples can also be caused by a quick change to shallow water depth. If the signal source is too strong, the sound may be more likely to reflect multiple times off the seafloor before being recorded by the receiver. It is important to monitor the Knudsen and make alterations to the acoustic signal sent to get more accurate depth profiles of the seafloor.

I designed and 3D printed more parts for Brendon and the Boatswain. It’s pretty fun, I feel that designing the parts has enhanced my creative thinking. I have also gotten better at problem-solving by seeing which parts did not turn out well and reconsidering the print orientation and what kind of infill to use.

We also brought out the sewing machine and made some covers for certain devices onboard. The debubbler on the water wall needs a cover so that it stays dark to prevent things from growing inside of the water. The 3D printer needs a cover to protect it from scratches or other wear and tear it could experience from being on the ship for a while. There are electrical boxes outside to control the cranes that also need covers to prevent rust or other buildup.

Aside from work, we saw more healthy polar bears with their cubs and I have learned how to identify certain whales and arctic birds. I learned how to play cribbage and won my first game. We have done other fun activities like spin class, volleyball, UNO, spoons, and even a Mario Kart tournament. We are departing the ship in a few days, and it has definitely been an amazing experience. I have learned some new technical skills, met a lot of interesting people, learned about different career paths I could pursue, and kept a journal of everyday activities. I am very thankful for this opportunity as a MATE intern, and I am excited to see where my career as an ocean engineer will take me in the future!

Me installing my 3D printed fluorometer mount to the rosette