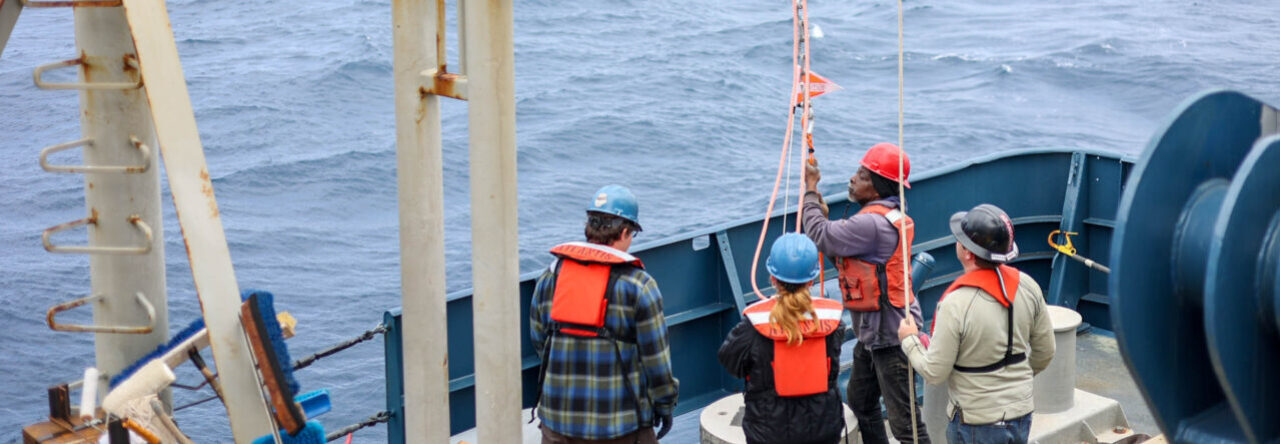

The cruise is nearing its end, having completed six weeks of travel. On July 18, around 8 am, the crew received a radio call from the Icelandic Coast Guard about a distress signal from a vessel with a broken mast and low fuel. The Marcus G. Langseth, being the closest ship, backtracked to assist. After about five hours, the sailboat was spotted. The crew deployed a small boat to deliver multiple cans of fuel to the stranded vessel, successfully enabling it to return home safely. It appears the boat had not been ready for the harsh weather, as their sails were shredded.

Continuing on, we passed Iceland on the west and entered the Arctic Circle, where the sun never sets. However, operations were suspended for several days due to poor weather. Upon resuming, we completed work at Station 6 east of Greenland, where we observed pilot whales and retrieved a core sample containing a piece of sponge. We then headed to Station 7, the final station.

We also experienced power disruptions due to engine issues; I believe the starboard main overheated and shut down, likely due to a procedure missed as we slowed down to deploy our last Argo float. Fortunately, the engineering team resolved the issue within a couple of hours.