Hello Readers!

This week was filled with a lot of new skills and intense moments working with the ROV!

9/25

Late this morning, we got to Gulfport and that meant that the Point Sur crew has to clean up around the ship! Since we docked a few days early than anticipated, we had a few days to fix things and eventually clean around. I went ahead and focused on what the marine tech needs to take care of which is our precious flow thru system.

To clean this system, we have to run the system with freshwater for 10 minutes through the debubbler and 10 minutes through the rest of the flow thru system. To clean it, we close valve #1 and #2 which closes the saltwater input and closes the input to the rest of the flow thru system. Then we open valve #3 and run freshwater through the debubbler for 10 minutes. Then once that is done, we open valve #1 to run freshwater through the entire system!

I then cleaned the CTD sensors again with the same method I mentioned in my last blog post where I cleaned the sensors with Triton X, diluted bleach, and DI water. I slowly pumped the sensors with the chemicals in order and then did a freshwater rinse to clean the Niskin bottles.

Once I was done cleaning the sensors, I helped Grace replace batteries on an UPS system. An UPS (Uninterruptible Power Supply) is a system where you can backup technology and other devices in case of a power outage so that the technology can still function without shutting down. This is important on ships because we need systems to continue working despite a generator randomly shutting down or losing power because of an incident. We have a lot of sensors that the ship and the science party is dependent on like GPS, internet, navigation, all of our science systems. Me and Grace carefully took out the old UPS system from the tech rack and slowly opened up the battery rack (since batteries from an UPS system might explode). We made sure all the batteries are safe enough to replace and went ahead with detaching and installing the new batteries. This took a lot of strength to take the batteries out because they were stuck on the UPS system with double sided tape. Everything worked out in the end and we put the UPS system back in the tech rack!

Once we took care of the UPS system, we went ahead and focused on the main mission of the day. Grace keeps a well-organized list of sensors of their model, serial number, last calibration date, and next calibration. There was a long list of sensors that needed calibration so we first filled out an RMA order from Seabird. Most of our sensors were from Seabird so we added all of them to a single RMA order to make things easier (although the site kept crashing when we tried submitting the order haha). We also had sensors from RM young and Biospherical Instruments, so we went ahead and emailed tech support for an RMA number to send them in for calibration. Once that was all done, I went ahead and gathered most of the instruments (the weather sensor is on the mast of the boat so I will learn how to dismantle it tomorrow), and found pelican cases for them to be safely shipped in.

9/26

Today we are at the wooden dock in Gulfport and have a few things to get in order. The main thing is getting the weather sensor from the mast, which is located at the very top of the ship! Me and Grace agreed to replace the weather sensor in the morning to avoid the hot sun and we started the trek up with a bucket full of tools and some rope to haul in the bucket from below. Replacing the weather sensor with a newly calibrated sensor was fun for me despite being so high up and although it took a bit for me to learn how to do it, I still enjoyed it!

We took the old weather sensor down and went to the tech lab to test the new weather sensor. We put power back to the weather sensor button and tried connecting to it but an error popped up! The software kept recognizing the newly mounted weather sensor as the incorrect model number and wouldn’t properly connect. This is a bit ironic considering the newly mounted sensor just came back from calibration for the exact same issue! We tried troubleshooting it on our end using software’s like PuTTY and Tera Term by trying to display nmea feed to see if its outputting data and that would not work! We tried changing the baud rate (how fast information can go in or out of something) and it still wouldn’t work! I ended up emailing them the issue and they ultimately said to send it in for calibration once again which we did not want to hear. This meant that I had to go back all the way up to replace the weather sensors again and send in the messed up sensor for calibration once again.

We took a break and I asked about what the rope in the clear bag was and Grace explained to me that is was a yale grip. It acts like a winch cable protectant and a way to attach certain instruments like the ROV Beagle for our next cruise! This rope has to be tied around the winch cable in a specific way but it works just as great as its metal counterpart. Not only will the rope grip more tightly on the winch cable but will be easier for the ROV team attach and detach their tag line hook.

9/29

Since we were working with COM ports to troubleshoot the weather sensor issue, I asked Grace if she could explain what a COM port is. She explained that a COM port is a physical port on a computer or UPS that takes in as a serial port. Tera Term is a software that that access all COM ports on the tech lab computer. When we ran into the issue with the weather sensor, we first started troubleshooting on Tera Term. To test connectivity, we connect to the COM port using Tera Term and then it should display continuous nmea feed. If it isn’t showing nmea feed, then data isn’t been sent out of the weather sensor and there is something wrong with the connection. Connecting to the COM port with Tera Term wouldn’t worked so we switched to a different software. Just to be sure, we tried another software called PuTTY to access the COM port and that would not work either. I asked Grace what is the reason for having two different software’s that have the same purpose and she said that Tera Term can save the nmea files in a notepad format whereas PuTTY can’t save nmea files, only display them.

I also learned that COM ports run through MOXA boxes on this ship. MOXA boxes read data like a computer and can broadcast them over the internet to other devices, computers, monitors, and more! This type of wireless connection is preferred to avoid cable and wire issues when it comes to feeding it to different systems like the CTD, ADCP, SCS, and many other software. Side note, when accessing COM ports, if one COM port is being accessed by another system, you can’t access that same one since it’s in use. Scientists need this feed from the MOXA boxes and if they don’t prefer the wireless option, they can be directly wired to any MOXA box!

9/30

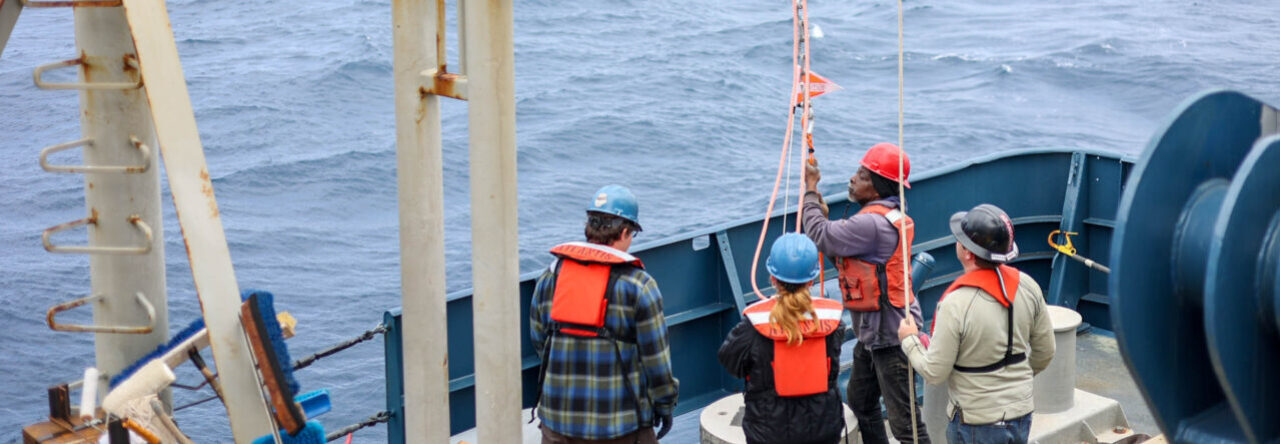

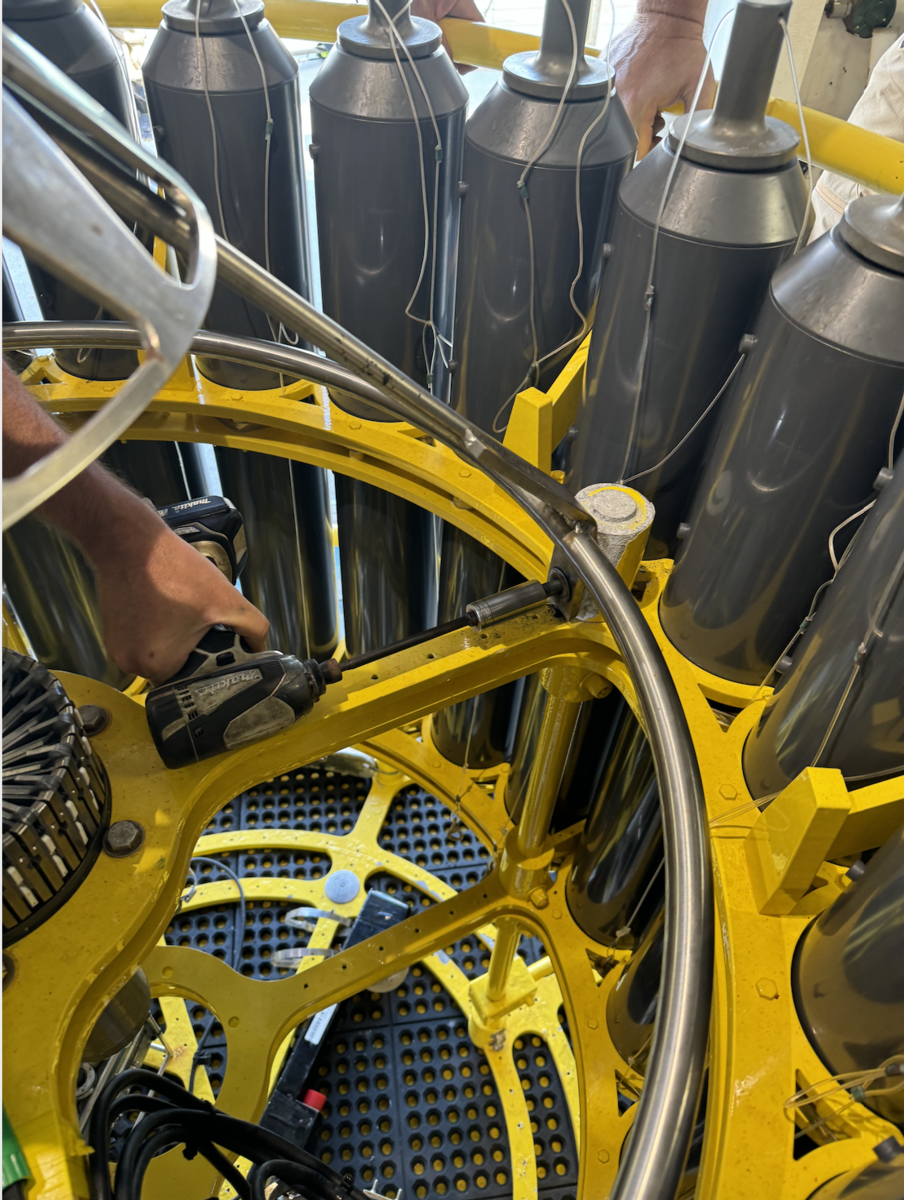

Today is our first day out in the Gulf with the ROV Beagle! The first deployment did not go so great since the ROV arm malfunctioned when it was attempting to grab some corals. The ROV was quickly retrieved and they repaired the arm in time for the next two dives which went well. What I quickly realized was that ROV deck operations were intense because there are multiple people on deck helping the ROV by guiding it out, controlling the umbilical cord, and tying the umbilical cord to the cable winch. I had to standby the A-frame and control when it came out so the ROV team can properly secure the umbilical cord to the cable winch along with other operations. I will admit, communication between the marine technician and the ROV team was very confusing since the ROV team radioed to the bridge directly and make decisions with the captain without advising us up until they needed someone to control the A-frame. What that meant for us was constantly check in with them and anticipate their next moves since they wouldn’t clearly tell us up until they are geared up, outside, and waiting on us, which was frustrating at times. I learned to take a step back and realized that them waiting on us is not a bad thing and we can take our time to have a moment for ourselves before getting out there. This means that since we as marine techs are on call, whenever they need us, whether that be during dinner or in the middle of our projects, we stop and go help deploy the ROV as a team.

Later that evening, we had night operations which were solely operated by me, and that meant I had to be in charge of the CTD casts and Chirp data! We had five stations we had to do CTD casts at, and thankfully the scientists only needed CTD data, no water samples! This would be considered yo-yo casts since we would deploy them to the bottom and make it come right back up. In between each station, we would turn on the Echo sounder Chirp at 12kHz to map the bottom of the seafloor. Although there were a few hiccups that evening, it was nothing major and we all ended the night happy with the data collected!

10/1

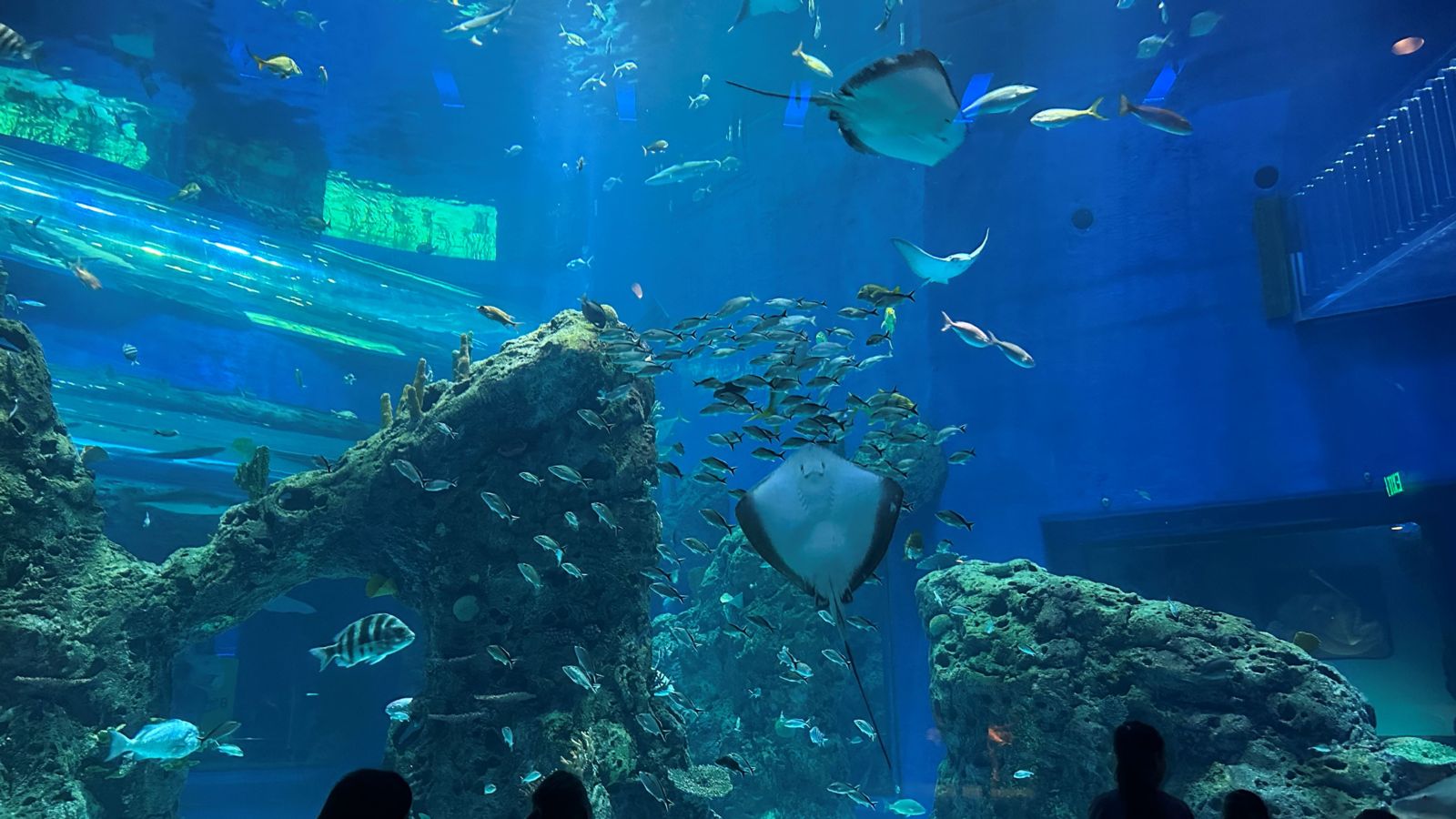

Today, we had two ROV operations, but the second one is what took the longest. The second dive took the longest because the science team wanted specific coral and took time to find, photograph, and retrieve samples of them. Although it was super long, it was fun for the rest of science party and the crew to watch what corals they found, what fish popped up, and saw some Spotted Moray Eels! While ROV operations were underway, I went ahead and asked Grace some questions on some skills and knowledge that marine technicians should be familiar with.

One piece of knowledge that marine technicians should know is what type of load is occurring when someone is operating a crane or machinery. Static load is when something is not moving at all aka constant pressure pushing against it. Dynamic load is an object/load that can be altered in position, magnitude and direction. If a force/weight is applied, the load turns from static to dynamic due to added weight to load. This is important when it comes to deck operations when out at sea and loading up the boat on the dock. Lots of equipment are static load until it is lifted up and then dropped back down on the boat with more weight due to gravity when on the dock. This changes when out at sea, with waves shaking the boat, it can alter the type of load when an instrument is moved around with added weight due to the rocking motion. This is all important to keep in mind when outside doing deck operations under any conditions.

I also asked Grace what a block is and she said it is a nautical term for a pulley. There are a few blocks on the A-frame that can help guide cable or rope (called soft line) but they all vary in size. I asked why that is and she explained how the diameter of the cable or rope can’t be bent too far into an angle. Basically the bigger the block the thicker the cable. This is important when it comes to deck operations because marine technicians and crew members need to keep in mind can the block hold the equipment’s weight? Can cable handle the weight or the shackles or the cable end? I did not realize beforehand this is something to always keep in mind and check on from time to time, especially after a few cruises.

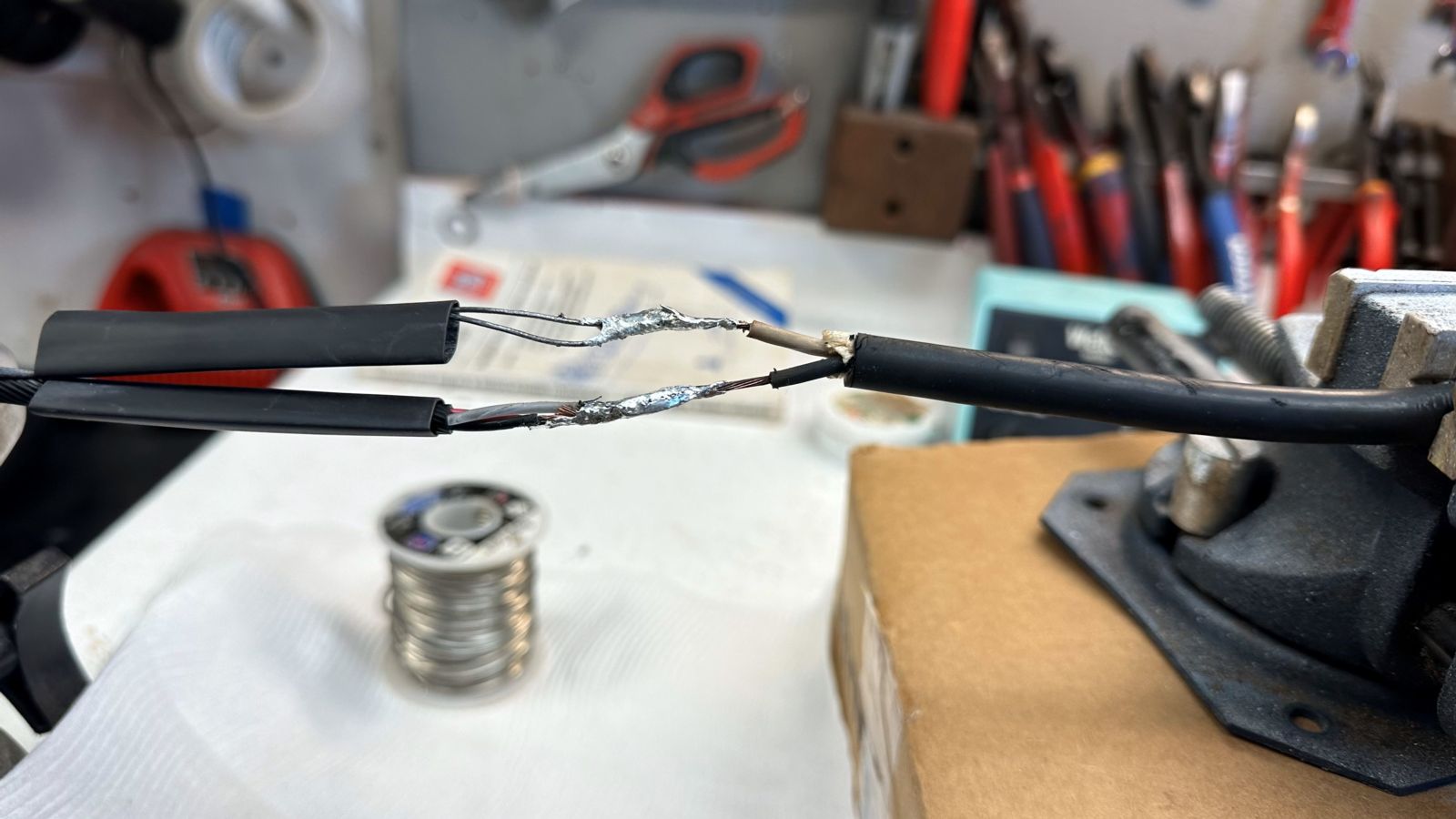

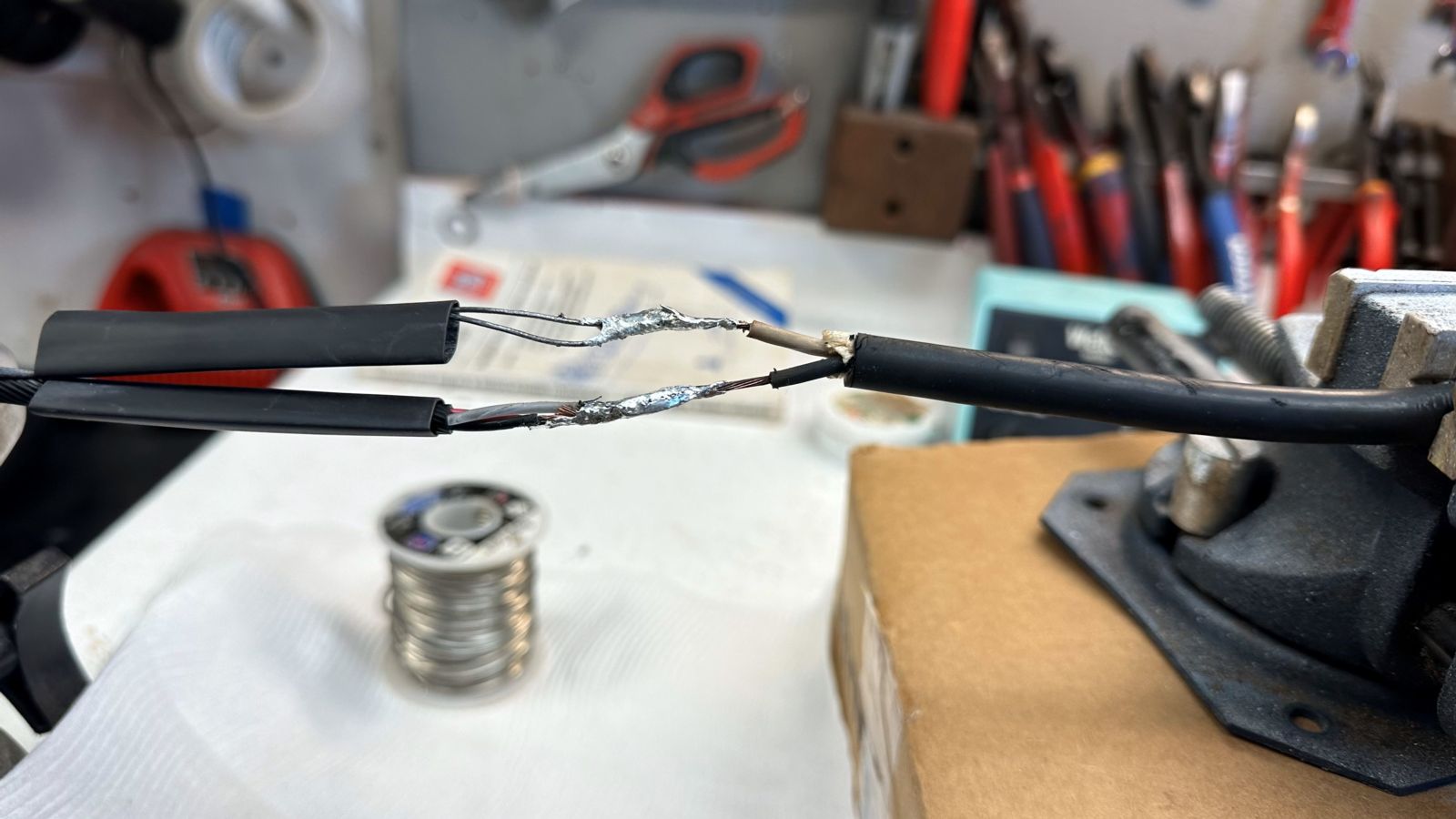

Since there are no night operations happening tonight, Grace assigned me a new cable termination to complete and since making one takes quite a while I went right to work! It took me a bit longer since I accidently cut the outer metal shield too short and the pigtail cable couldn’t reach it fully, it still worked out when it came to soldering! I used a new heat shrink size that I found that fit perfectly over the pigtail cable head and shrank it down to a good size! This one turned out to be the best one I have made despite a few mishaps here and there but I tested the continuity and it works!

Look how pretty my termination looks!

That’s all I have for this week, tune in next time to hear more!

Kristine