DeMob Mob Party (Dec 10th – Dec 19th)

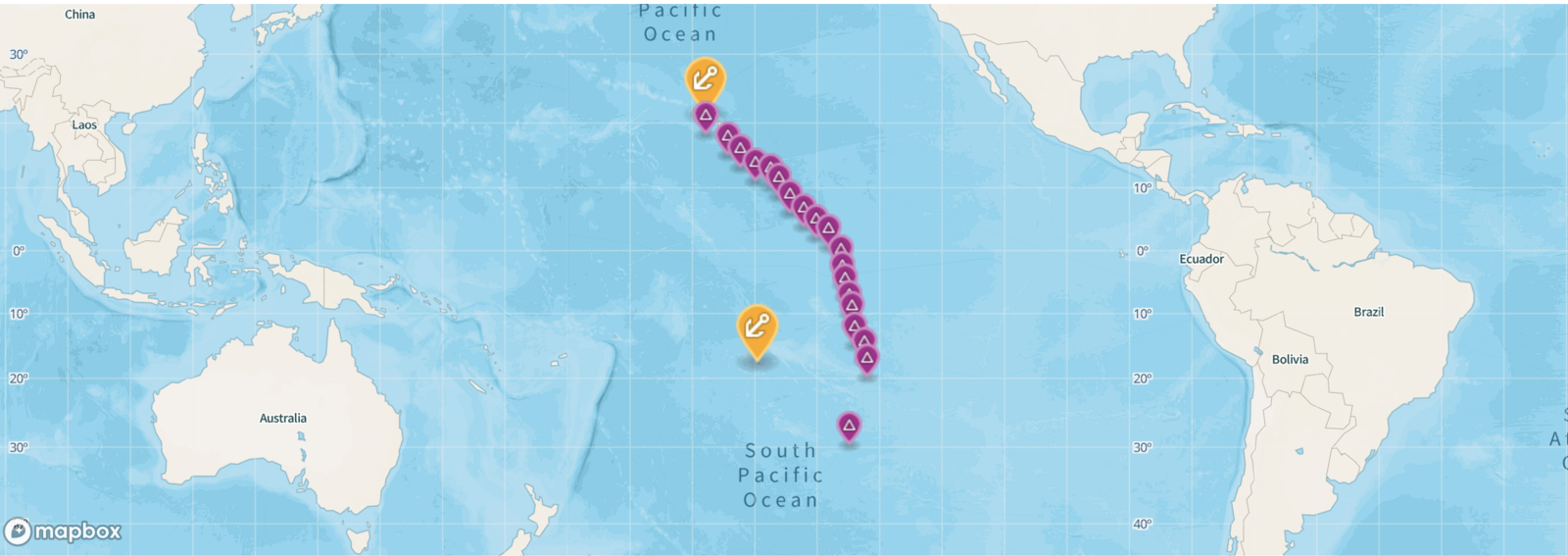

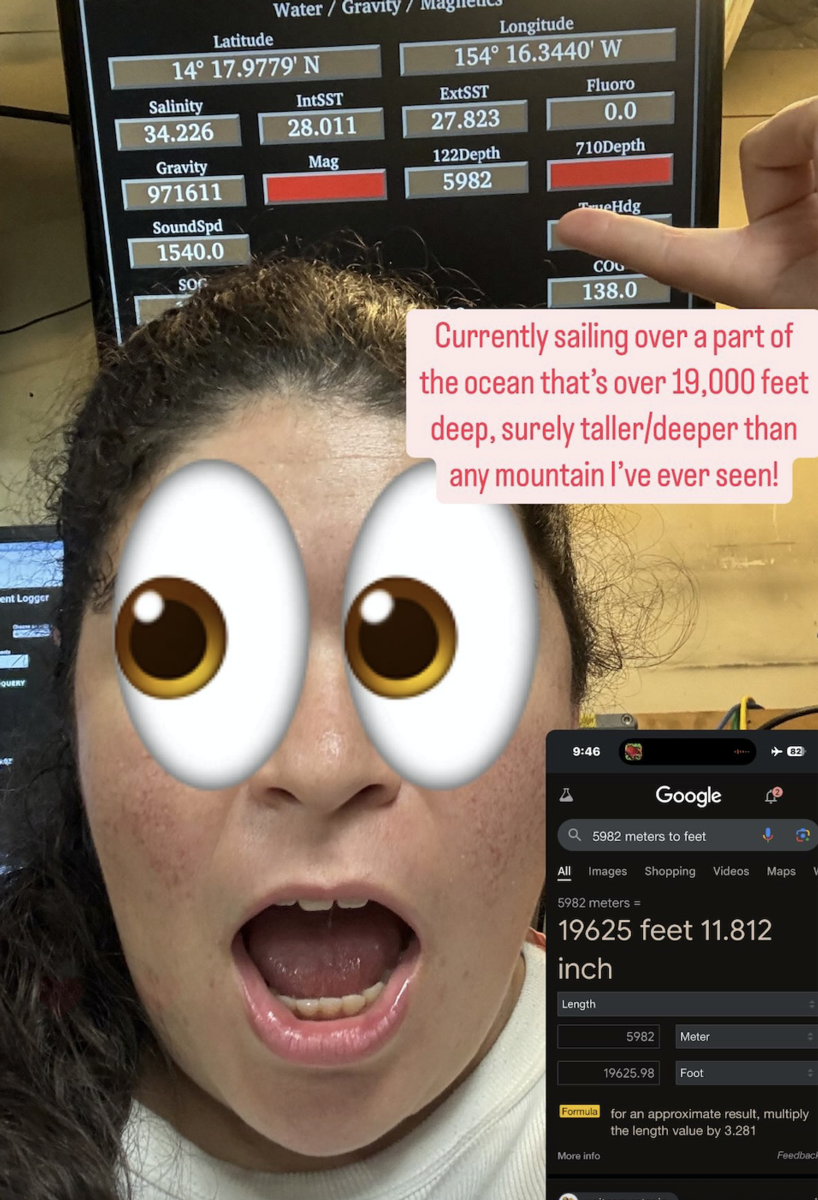

While in transit back to Honolulu, HI from Tahiti, the Kilo Moana team was tasked with collecting a sea glider that had lost its way home. Unfortunately, the glider had a damaged compass board, which made the $300,000 instrument disoriented. Futhermore, its battery was near close to dying with only 14% battery left which would make it unrecoverable due to the inability to track it.

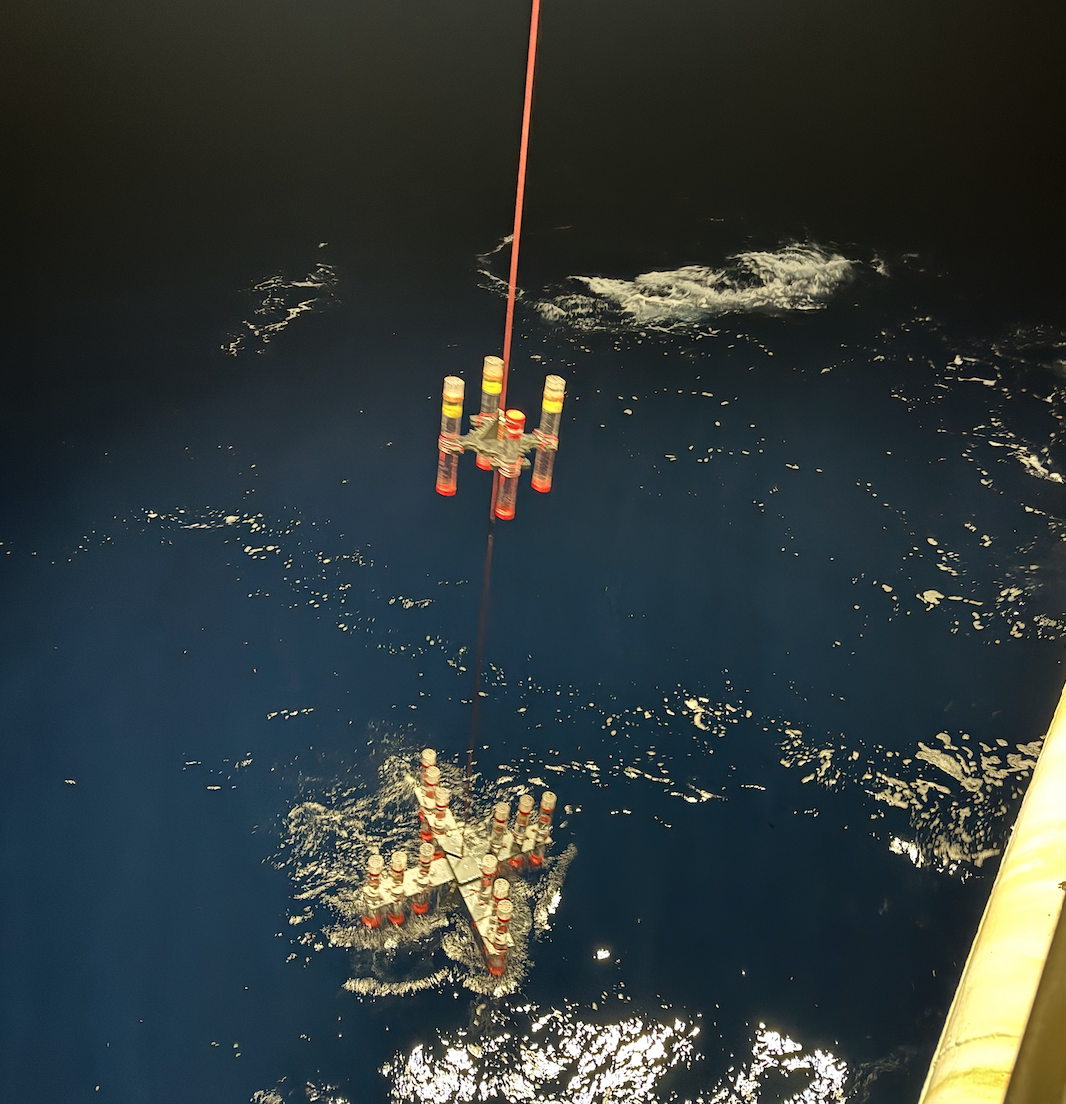

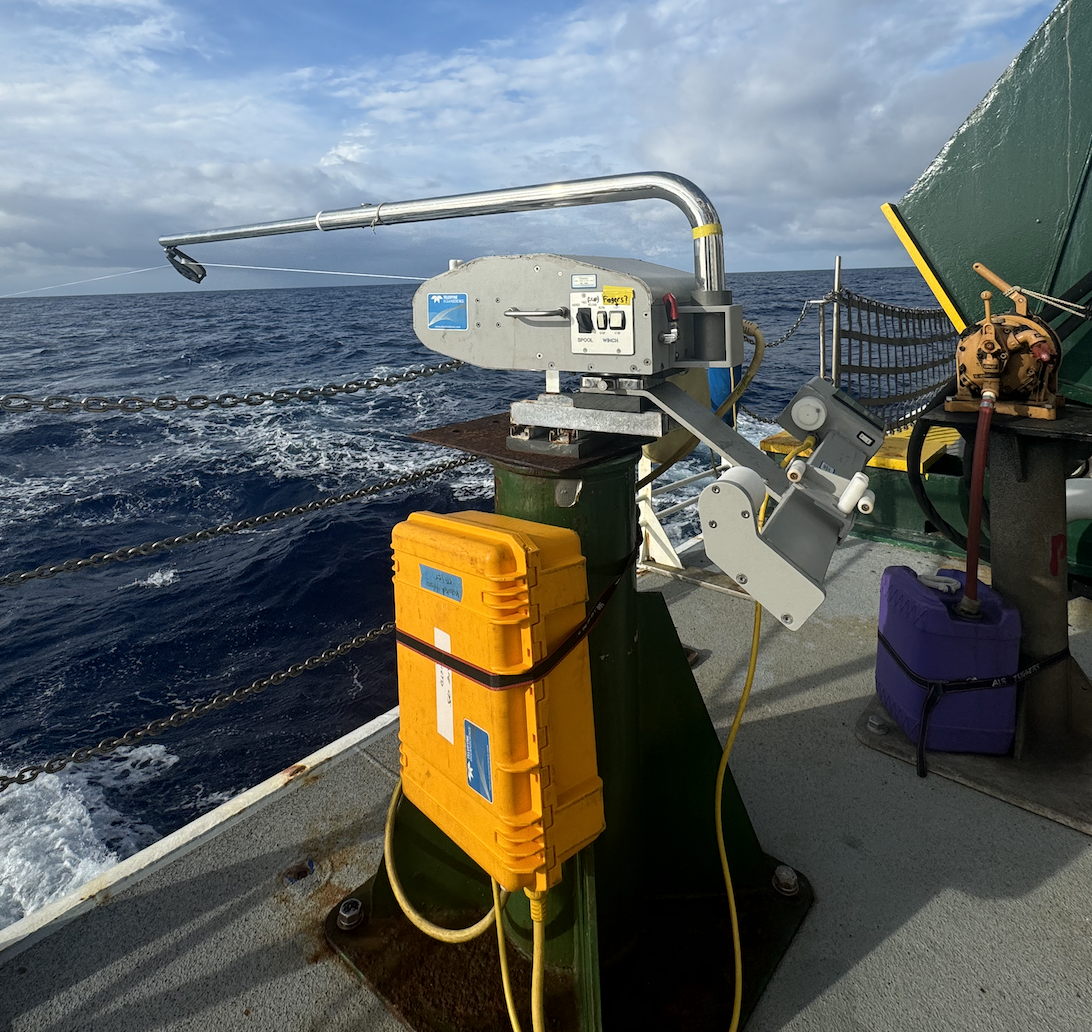

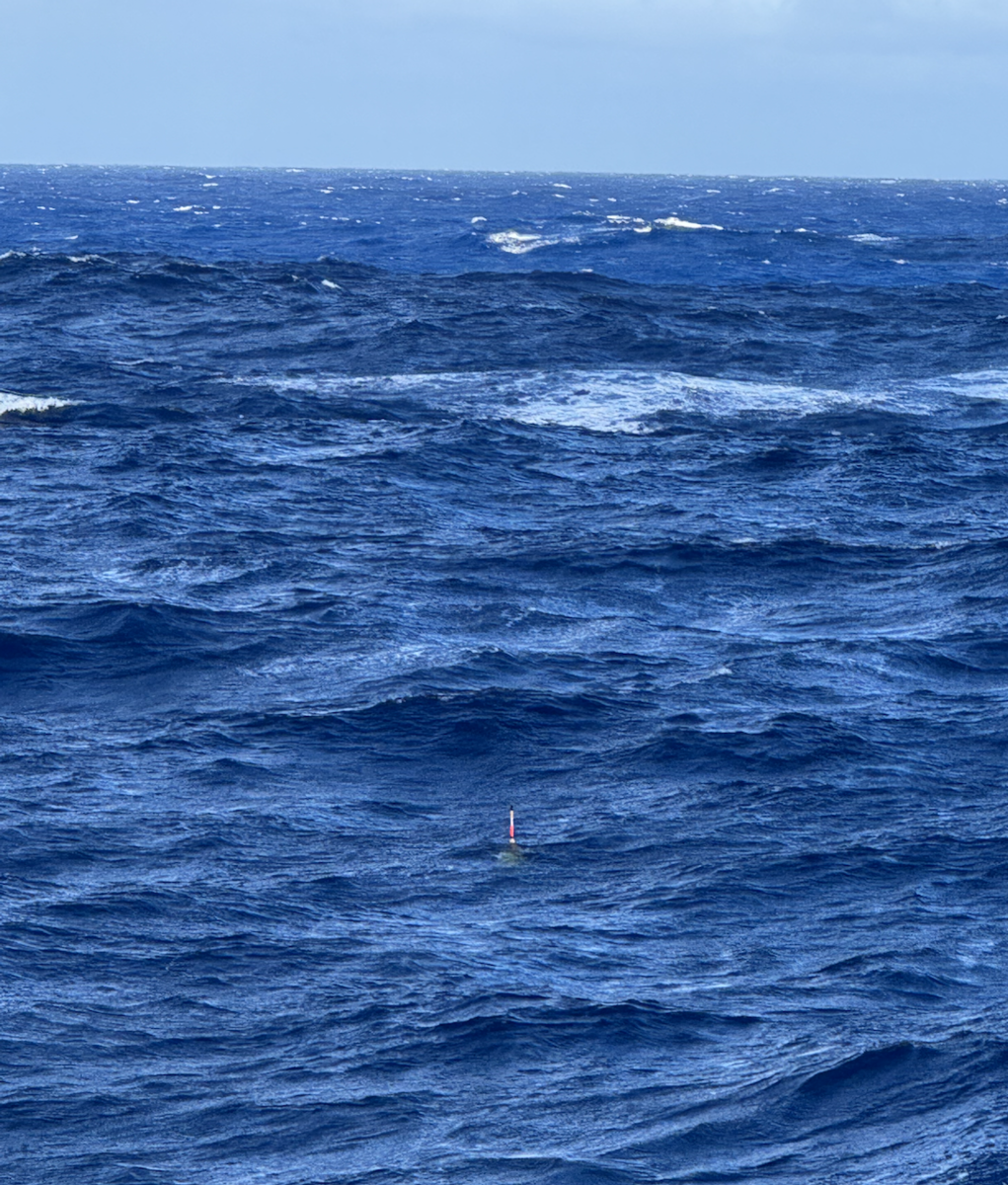

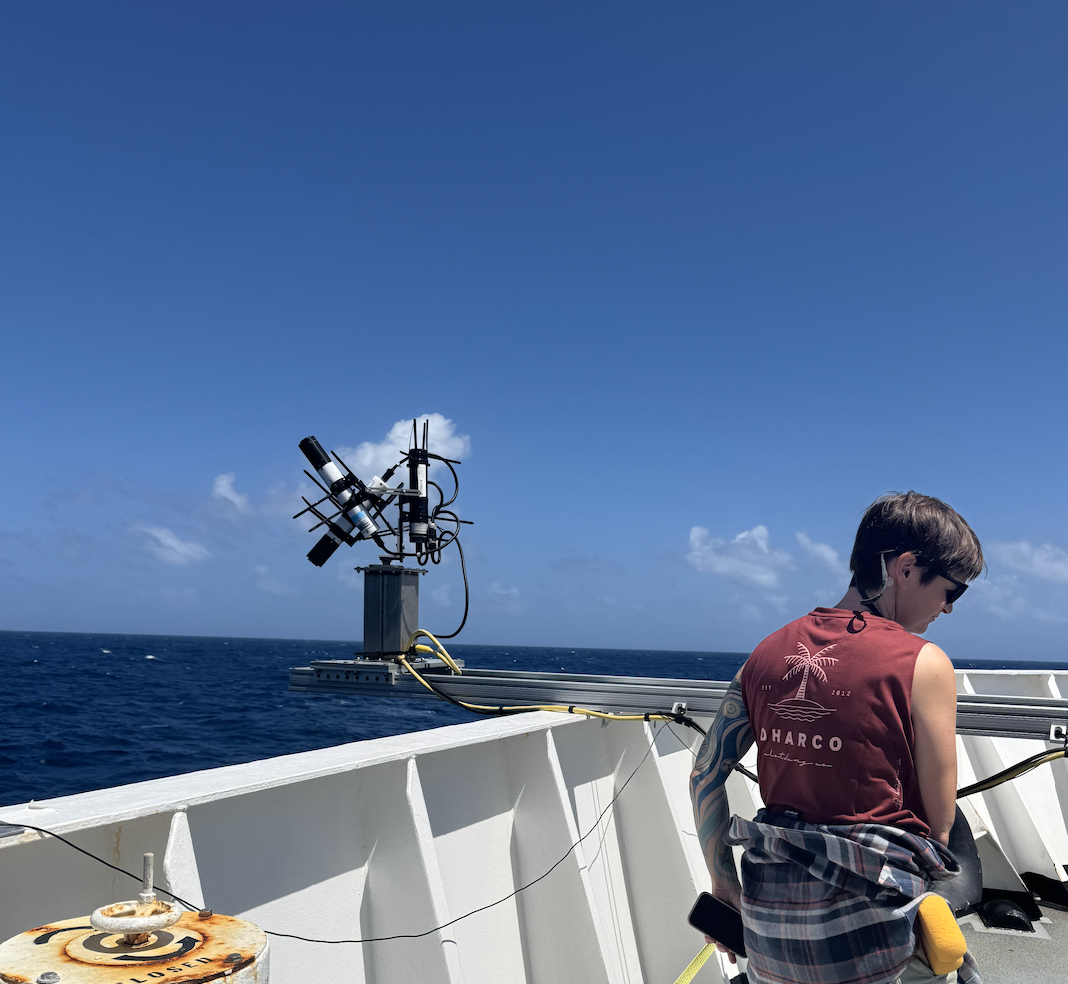

The glider was about 200 miles away, so we slightly rerouted to pick it up. The whole operation was a test of patience and trust. Due to its erratic flight path, it was decided that the best way to retrieve it was to back down on it, which meant turning the stern to the waves and risking waves crashing onto the back deck… which happened. Keeping an eye on it, felt a bit like searching for a needle in hay stack, as it had a tiny attena that would bob in and out

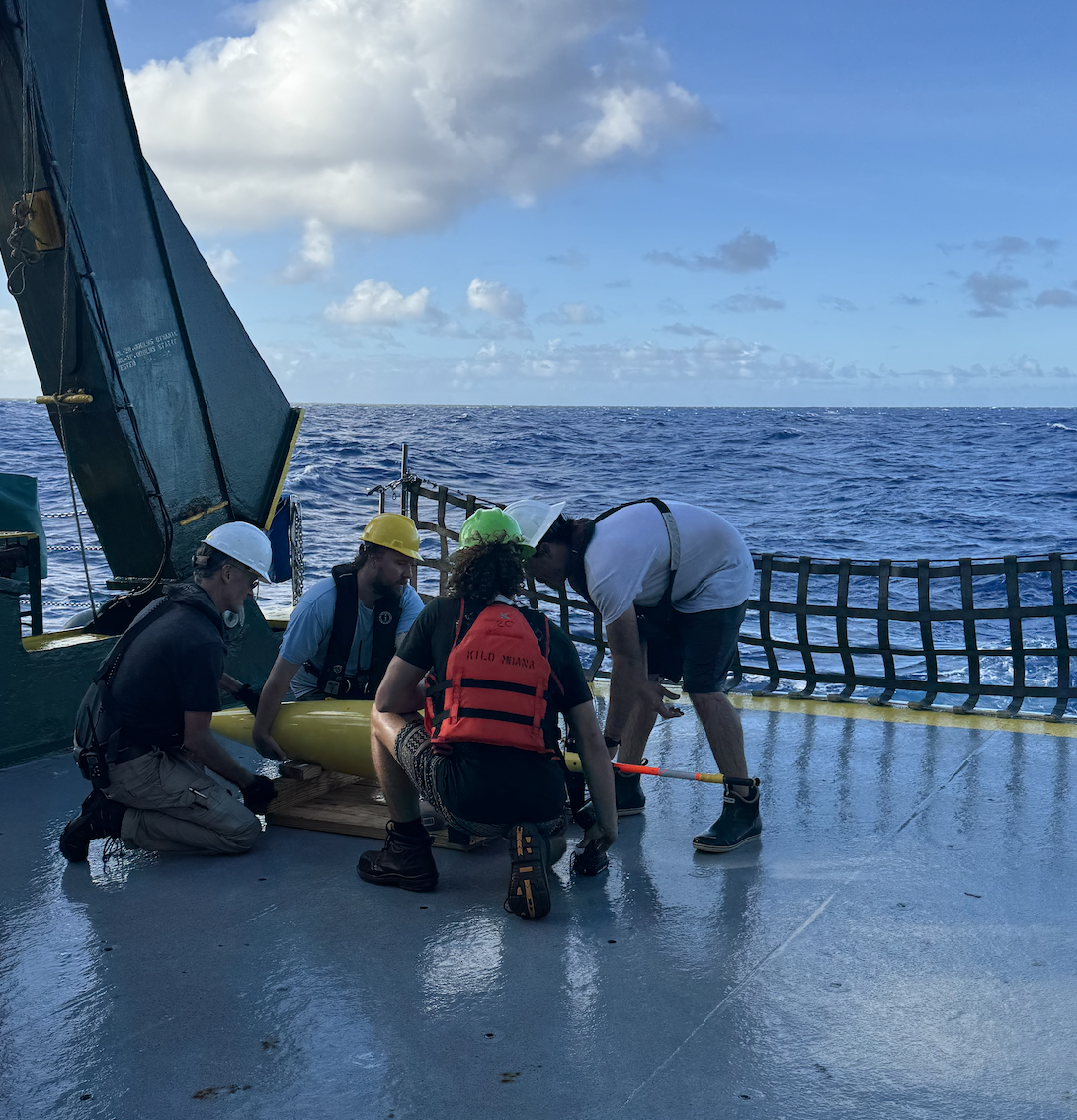

The Office Technology Group (OTG) also faced the challenge of bringing the glider onto the vessel during a high swell period, where it could take the glider from being feet away from the stern to being 15 feet below the ship. It was a high-stakes operation because you don’t want to be too close to the glider, where it can go below the ship and get crushed, which would virtually destroy the instrument.

Thankfully, none of that happened, and after 3 hours of trying, we were able to bring the glider onto the ship and start heading back to Honolulu. We arrived on the outskirts of Honolulu on the evening of Dec 15th. It was surreal seeing Honolulu, HI appear on the horizon, first as a tiny ridge that could easily be confused for low-hanging clouds, then as a shimmering city situated at the base of the Ko?olau Range. Due to the uncertainty we faced regarding our arrival time at the port, customs assigned us an appointment for Dec 16th at 7 am. Despite having arrived at the vicinity at least 12 hours before, we still had to wait for our appointment.

Meanwhile, that evening, Hunter and I helped Dr. Ali Chase clean and pack away most of her instruments: Hyper BB, LISST, IFCB, ALFA, FRRF, ACS, and pySAS. As a team, we got most of it done and went to bed at a reasonable hour. The following morning (Dec 16th, 2024), we were quickly cleared for customs and allowed to enter the harbor. Once we reached berth #35, we were greeted by the Agriculture people, who checked the ship before finally clearing us to open the gangway and let people off. It was nice to be back on land. Going out to sea is fun, but it also makes you appreciate land just a little bit more.

Once the gangway came down, a whole bunch of HOT people came to help us unload. The crew was busy craning vans off the ship, enforcing safety, and mobilizing. Since we were taking stuff off the ship on foot, we loaded it onto the UH Van and dropped it off at a beach lab. I ended the day with a solid 20,000 steps, which says a lot about how much there was to unload.

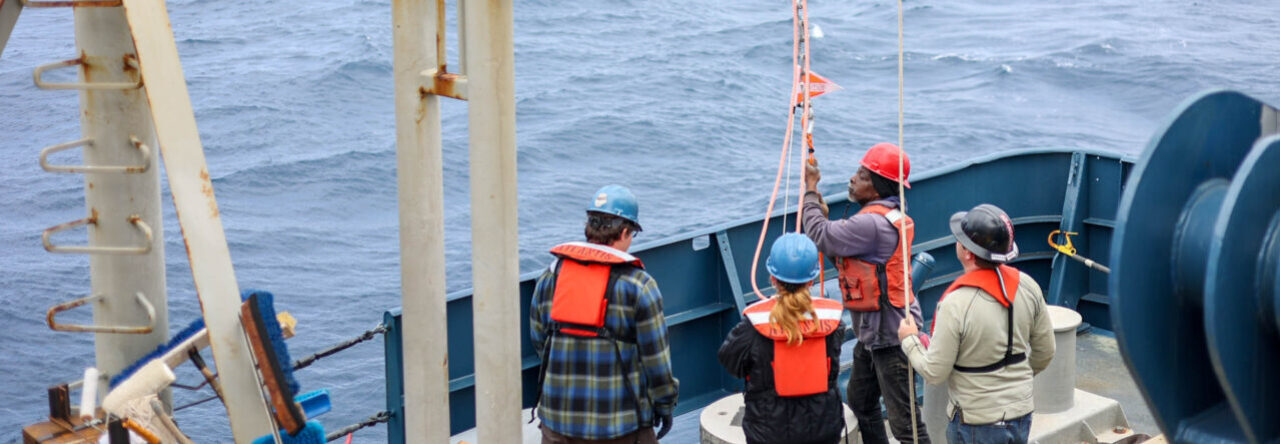

The following day was also jam-packed, with everything that hadn’t been finished unloading the day before and the mobilization for HOT Cruise #355 happening the following morning. After my first HOT cruise, I learned that due to the holidays, there were few volunteers, so I asked if I could volunteer after we got to port, since the HOT Cruise #355 was set to sail a day after the Tahiti cruise. Thankfully, I was accepted to volunteer, and my internship was subsequently extended a few more days. This was exciting as it would allow me one last opportunity to revisit all the things I learned during the first week of my internship and see how much I’ve grown.

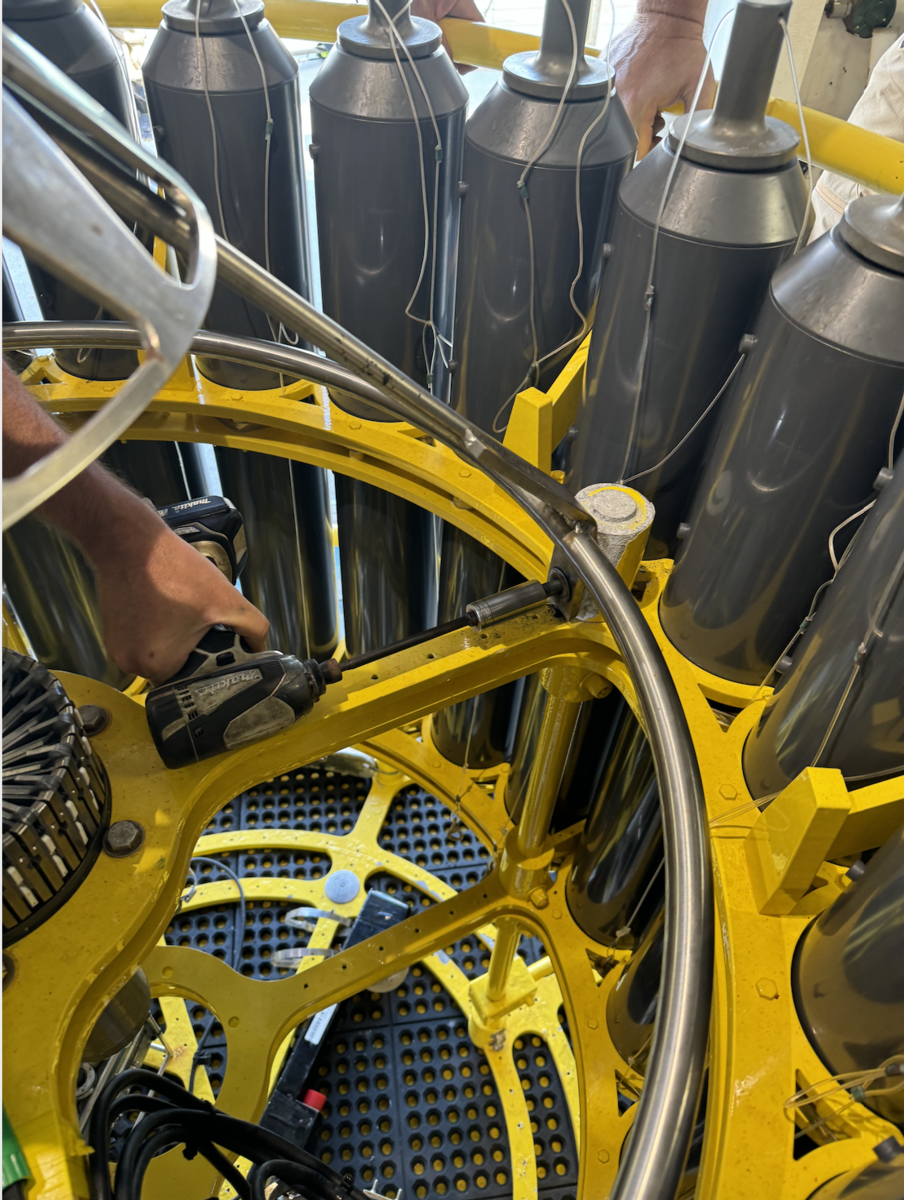

Dan Fitzgerald and I worked on creating a new termination for the CTD! It’s a HOT cruise tradition to always re-terminate before a HOT Cruise to prevent any issues, but this time, Dan let me take a bit more ownership of it, letting me unravel the wire, clip wires, hammer in terminations, and more. It was nice to reflect on my first HOT cruise experience and feel how much more my confidence has increased in performing basic marine tech tasks. It felt like a great moment, given that the termination was one of the first few things I learned about when I first started my internship.

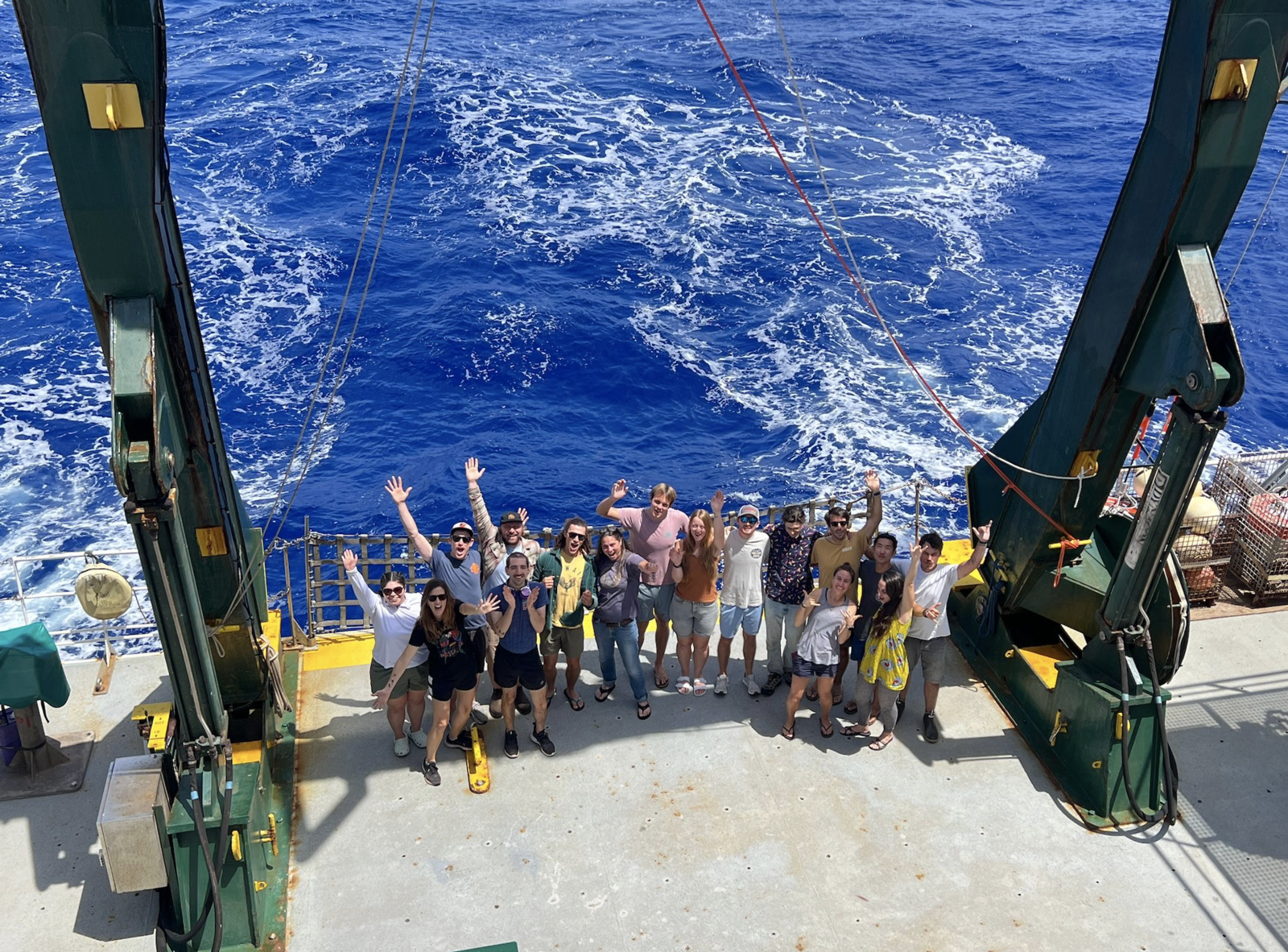

There are still a few more days left of the HOT cruise, and I’m going to savor every moment. It’s been fun working with this amazing team and always learning something new on the water. I am eternally grateful for the chance the HOT team took on me and only hope I can pay it forward by supporting more scientific expeditions across the UNOLS fleet.

Cheers,

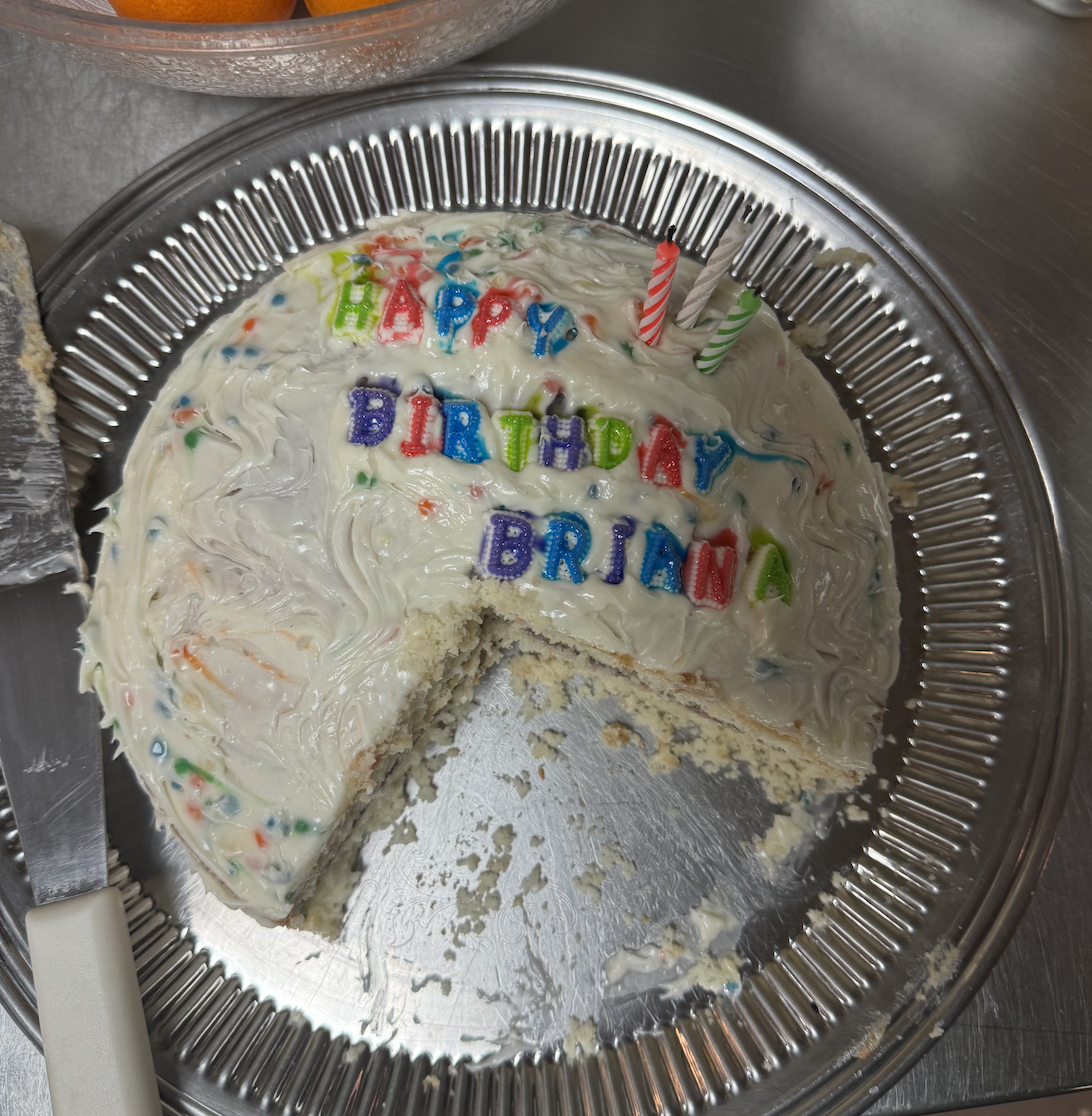

Briana

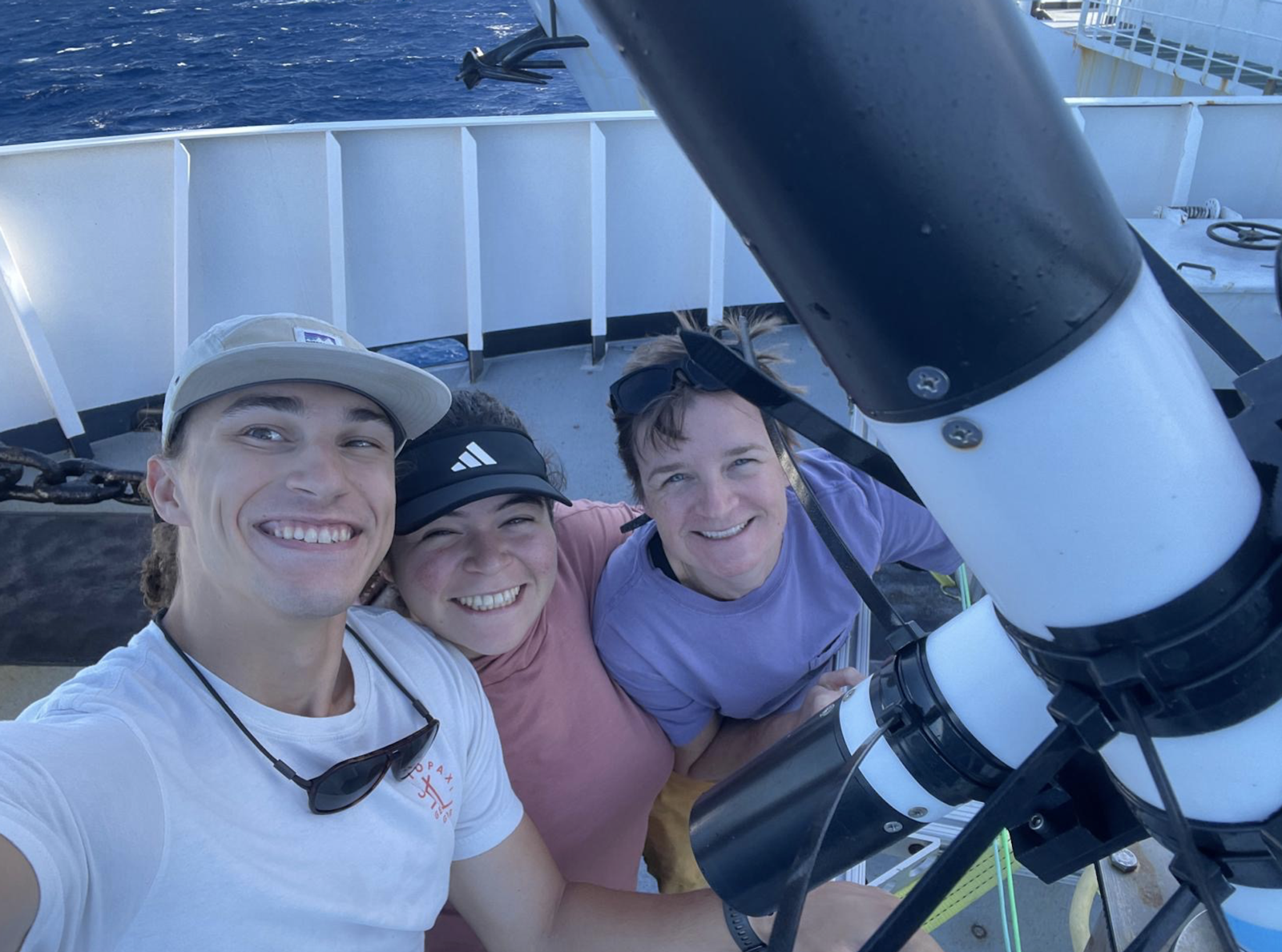

– Hunter Adams, Briana Prado and Dr. Ali Chase celebrating the last pySAS cleaning at the bow

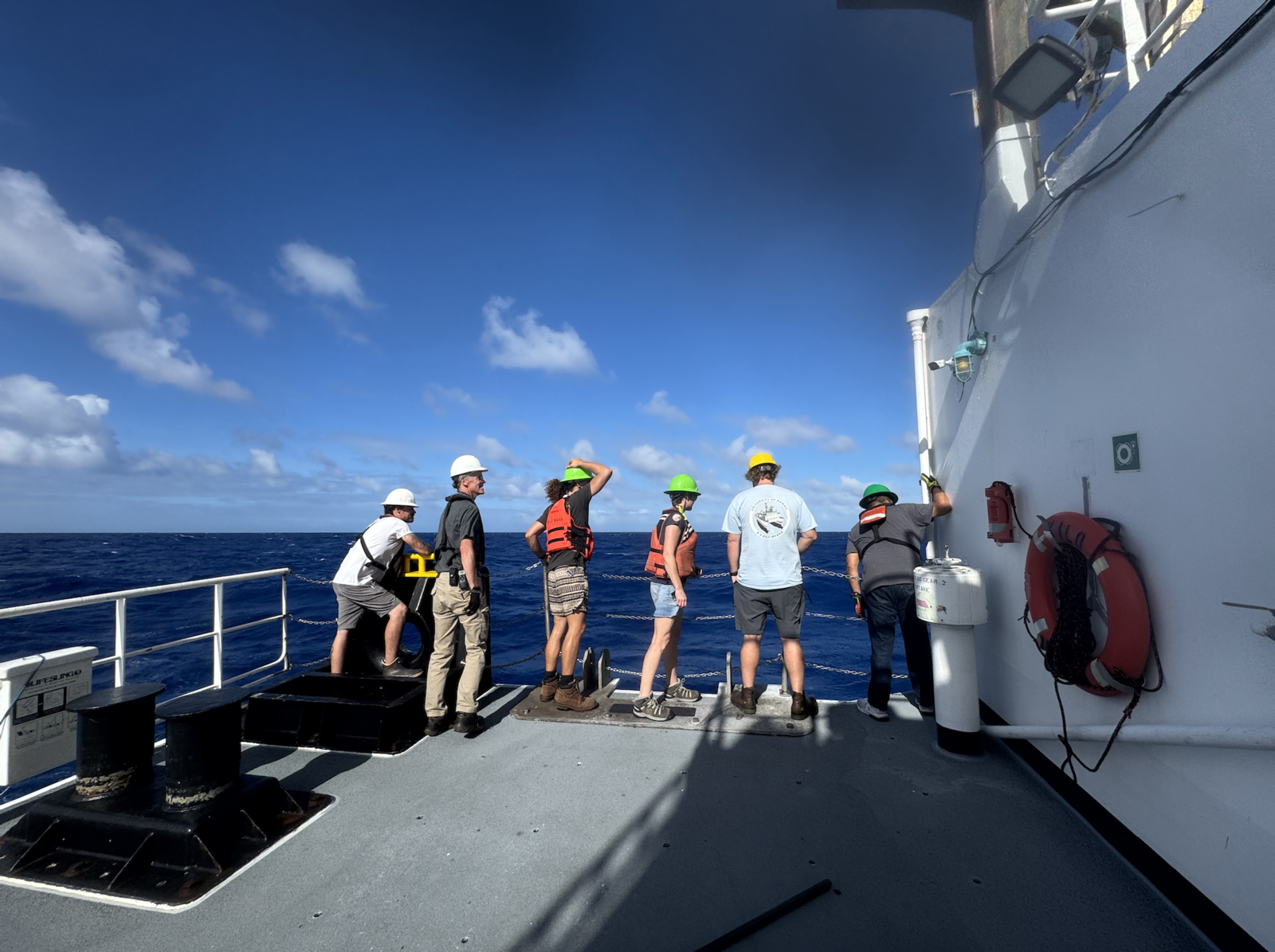

– Folks looking for the Glider on the port side of the ship

– This photo features the little attena that pokes out from the glider I’d like to call it Looking for the “needle in the hay stack”

– OTG and Chief Mate investigating the glider for any damages

– Glider safely on board after a suspensful 3 hr operation

– looking at Honolulu from a couple miles off shore waiting for our Border customs appointment the following morning

Bubble Troubles: Week #9 12/02/2024 – 12/09/2024

Bubble Troubles: Week #9 12/02/2024 – 12/09/2024

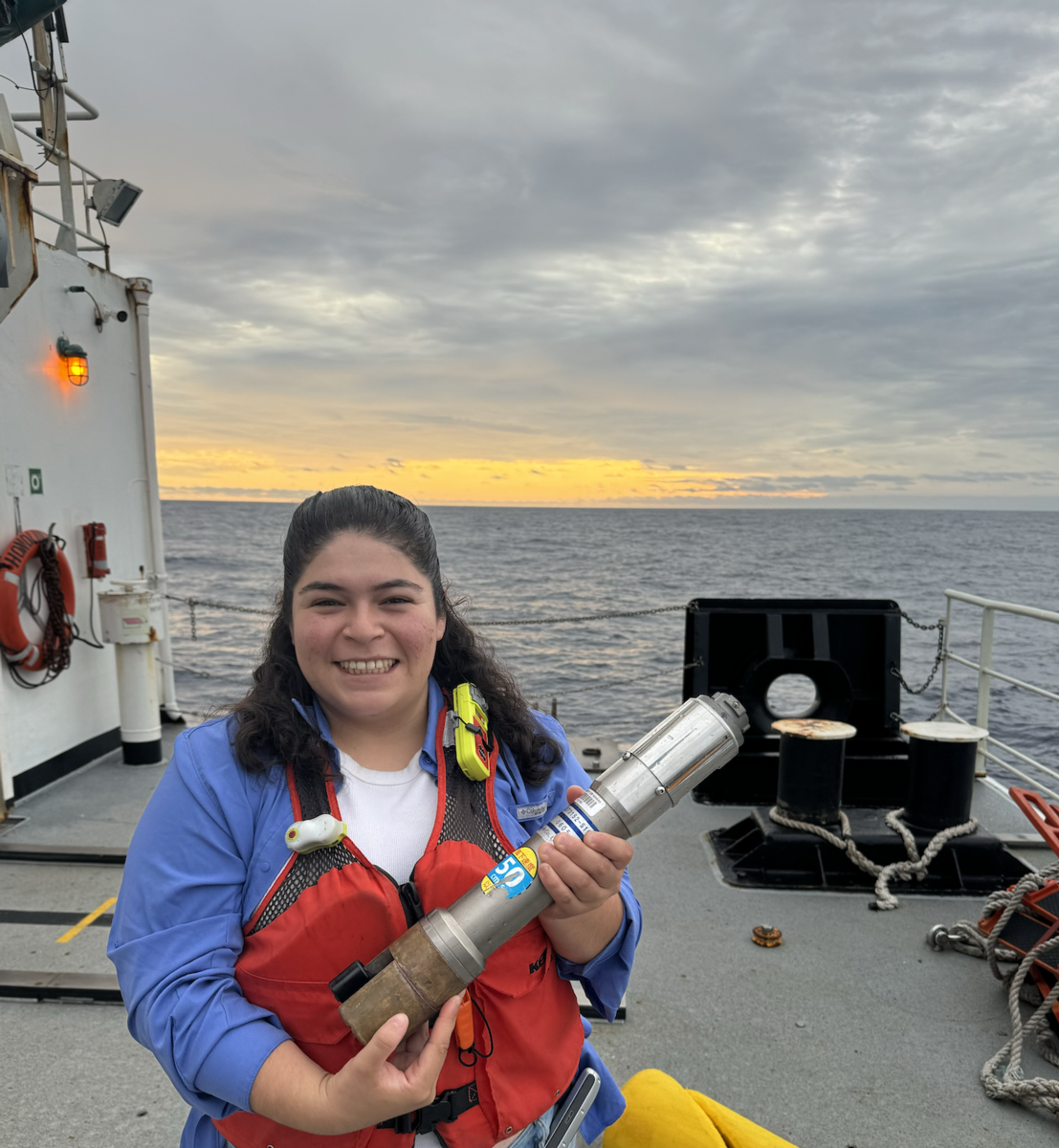

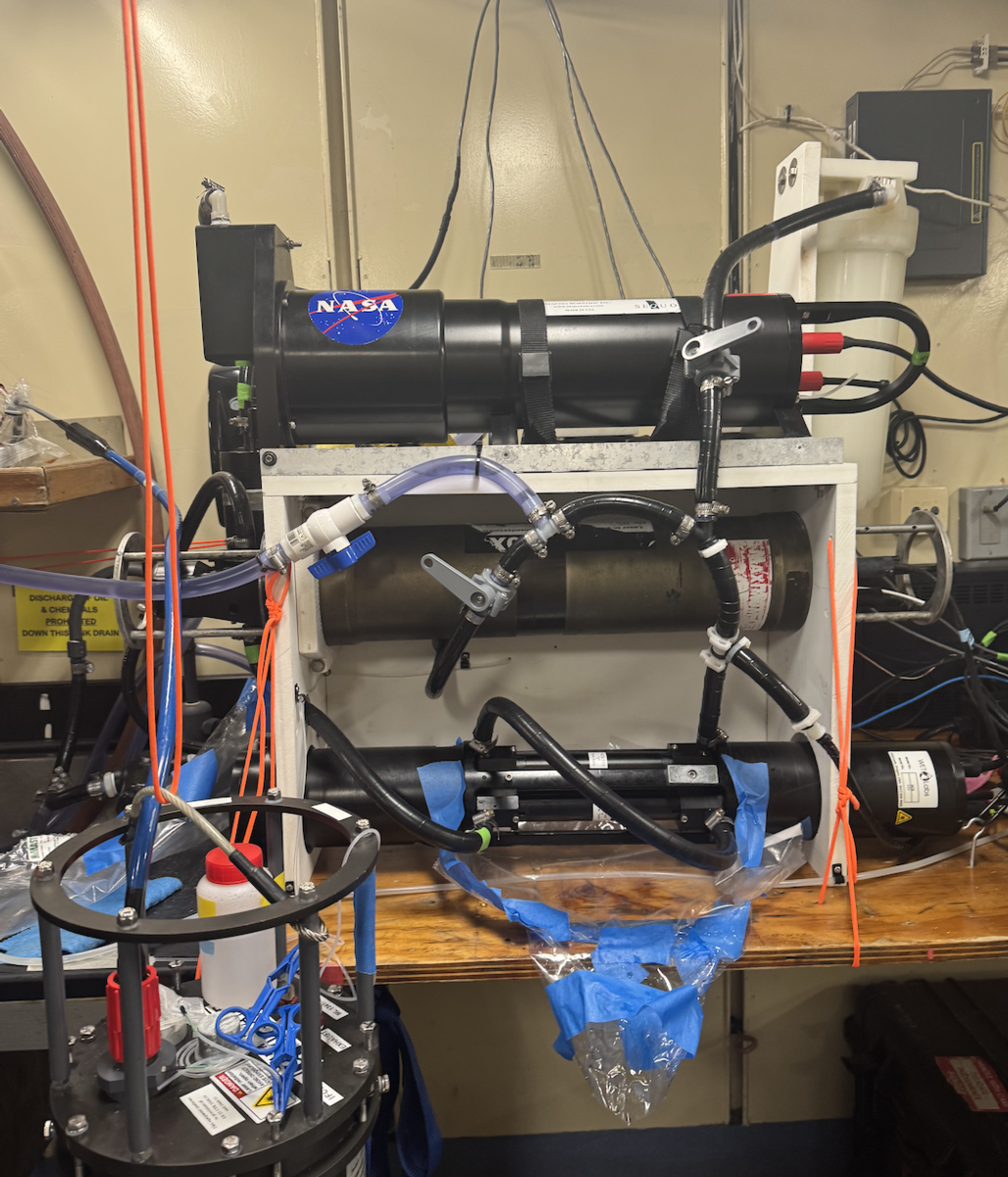

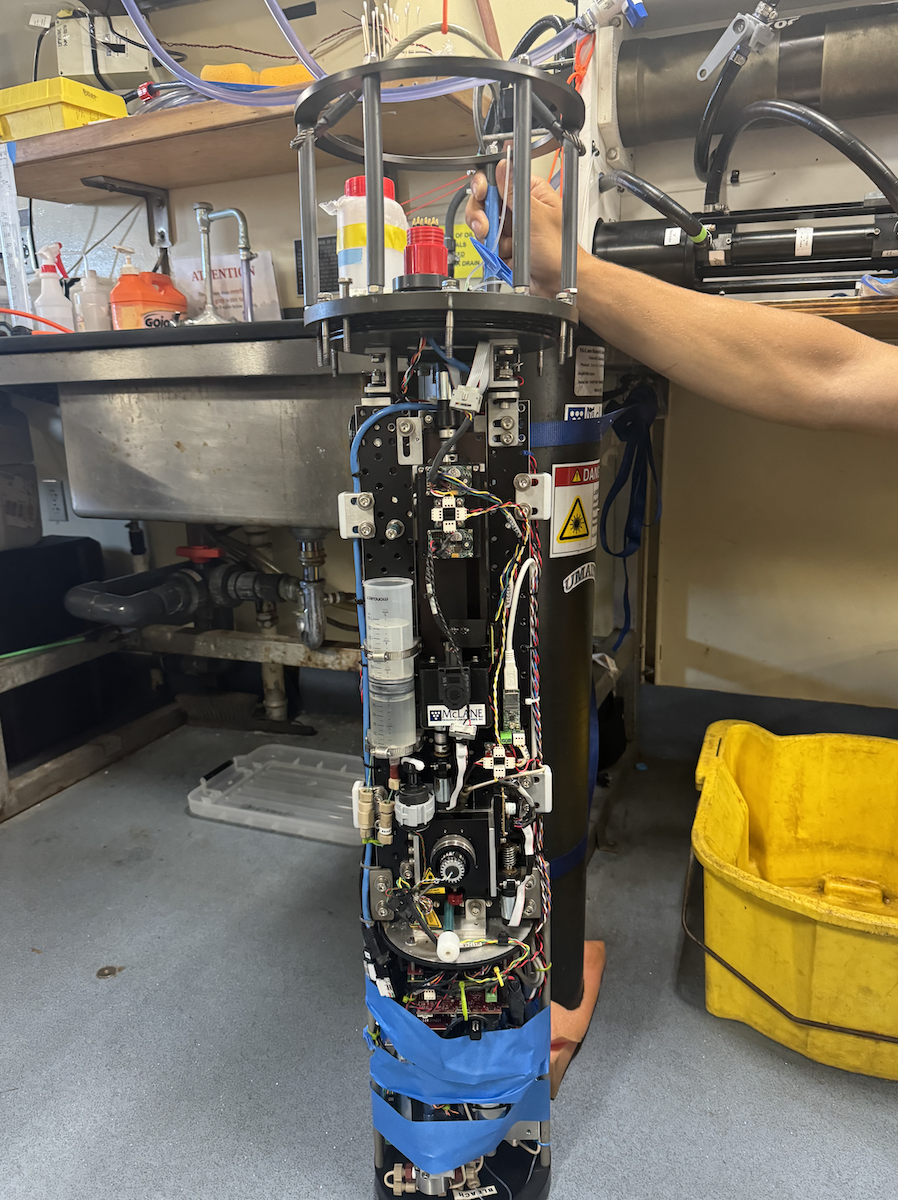

– IFCB outside of its Titanium Case

– IFCB outside of its Titanium Case