Practicing Diligence at Sea: Week #6 (Nov 11th – Nov 17th)

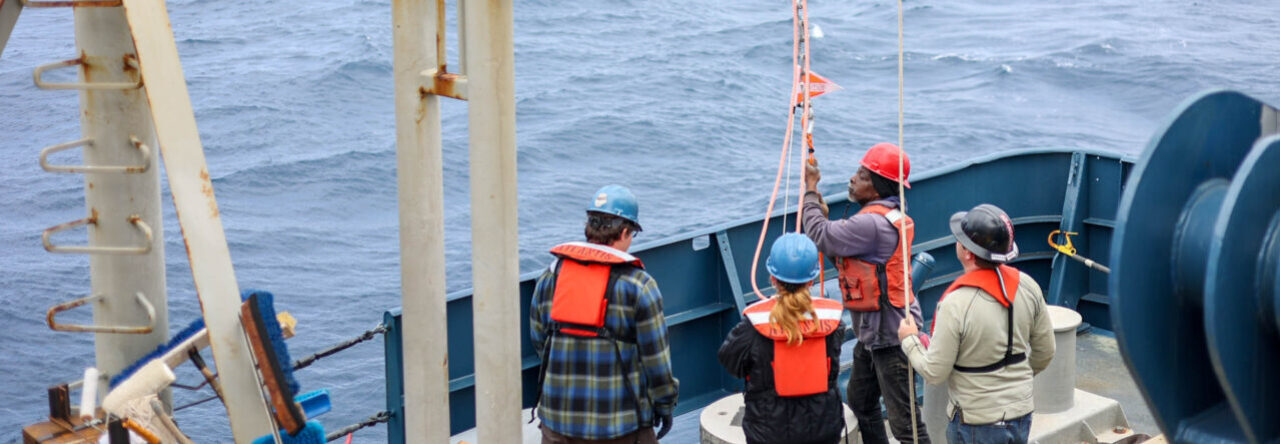

Safety at sea cannot be understated. This week, I had a few close calls while conducting back-deck operations that have made me acutely aware of the importance of preventing issues before they have the opportunity to escalate.

While deploying the wirewalker at the fourth station, we had an issue with the quick release. A clamp that is supposed to release when you yank it. This release transfers the load from the main line to the release when it’s time to release the buoy onto the water. It’s essential to release the clamp at the right time because if not the buoy and its packages might get dropped into the water from a height and damage them. Or if you wait too long, it can become harder to release the clamp because there is no longer that tension that would allow it to release.

Well… when we were deploying the buoy, the rope on the clamp got twisted under the leading line in a way that regardless of how hard I yanked, I could not get the clamp to release. I now found myself progressively getting closer to the edge of the stern and playing an unbalanced game of tug of war with the buoy as the A-frame moved the package away from the ship. Despite the rope burn, I held on because I was scared that if I’d let go, I’d lose the buoy/clamp.

Tully and Ben stepped in with about a foot of rope left, but then quickly halted operations as it became apparent that the clamp would not release. By stopping operations we had enough time to think about our next step, which just meant, letting go of the rope, bringing the package back onto the ship, and trying again. No biggie. The alternative situation where I could have gone overboard trying to get the clamp to release could have been much worse. If you ever find yourself in a situation between your safety and that of the instrument, safety comes first. Of course, if we could mitigate any damage to the instrumentation that would be ideal, but not if someone gets hurt.

A couple hours later while deploying PP arrays, I was handing over the primary production bottles when the whistle on my life jacket got tangled with the samples I was holding. I only noticed this issue when I was about to pull away and couldn’t get too far because the whistle’s rope was now stuck to the line. Had we reached the point where we were about to deploy the sample, it would have taken me with it. So we took a pause to untangle my whistle and proceeded with the operation. The lesson was that it’s okay to call for an “all stop” to address an issue before proceeding and to be very mindful of things that can become snagged. Not doing so could have made this issue much worse.

Another thing to keep in mind while conducting back deck operations is rope bights and how you handle rope. It’s easy to be focused on collecting your sample from the line when all of sudden you find yourself in a bight that could tighten around your ankle or hands at any time.

It’s also important to not wrap the rope around your hands for the same reason. Instead, if your wrapping loops, wrap the loops on top of your hand instead of around and hold the center, this lets the rope slide through your hand instead of tightening around it. Last but not least be mindful of rope slacks from the A- frame, it can be easy to get entangled in them if you’re not paying attention to what’s happening to the rope overhead. It’s all in the details and situational awareness.

And of course, always wear your hard hat, life vest, and steel-toe shoes when conducting back deck operations, you never know what could fall or roll onto you, but it really is just a factor of time until something does.

Other than some close calls, I’ve been doing good. We have now completed Long Station 3&4 and are now en route to our last long station, station 5. Stay tuned for more updates!

Cheers,

Briana