End of Cruise: CTD Wrapped (11/17 – 11/24)

A significant portion of the work fellow MATE Intern Hunter and I did consisted of taking Conductivity, Temperature and Depth Profiles (CTD) work in two main forms; underway CTDs and CTD Rosette Cast. Over the course of this 34 day cruise, Hunter and I completed over 161 underway CTD and over 101 CTD Rosette cast, generating a nearly complete data set of a transect from 21No to 27 So.

Our 161 underway CTD cast also appears to break a couple of records by a long shot. The second, third and fourth data sets contain an already impressive 83, 48 and 45 uCTD’s, but we doubled it!

Our mentor, Tully Rohrer praised us in casting over 161 underway CTD and experiencing very minimal problems besides some mechanical issues that came with wear and tear of the instrument. Tully once painful recalled how there was a cruise where the team kept getting tangled or as Tully calls them “Wuzzles” and how long and hard it was to untangle the line for hours. Thankfully we didn’t run into any issues with that, phew!

– Tully Rohrer rinsing the underway CTD to start packing it up at the end of the cruise

I really enjoyed casting the uCTD’s because it gave us an excuse to go out and stare at the ocean every 2 hours for about 25 minutes. I was being silly one night and calculated that over the 161 cast that we completed that we both stared at the ocean for a cumulative of over 60 hours or about 30 hours each! Pretty crazy if you ask me, but super fun!

– Fellow Mate-Intern Hunter Adams and I celebrating our last uCTD

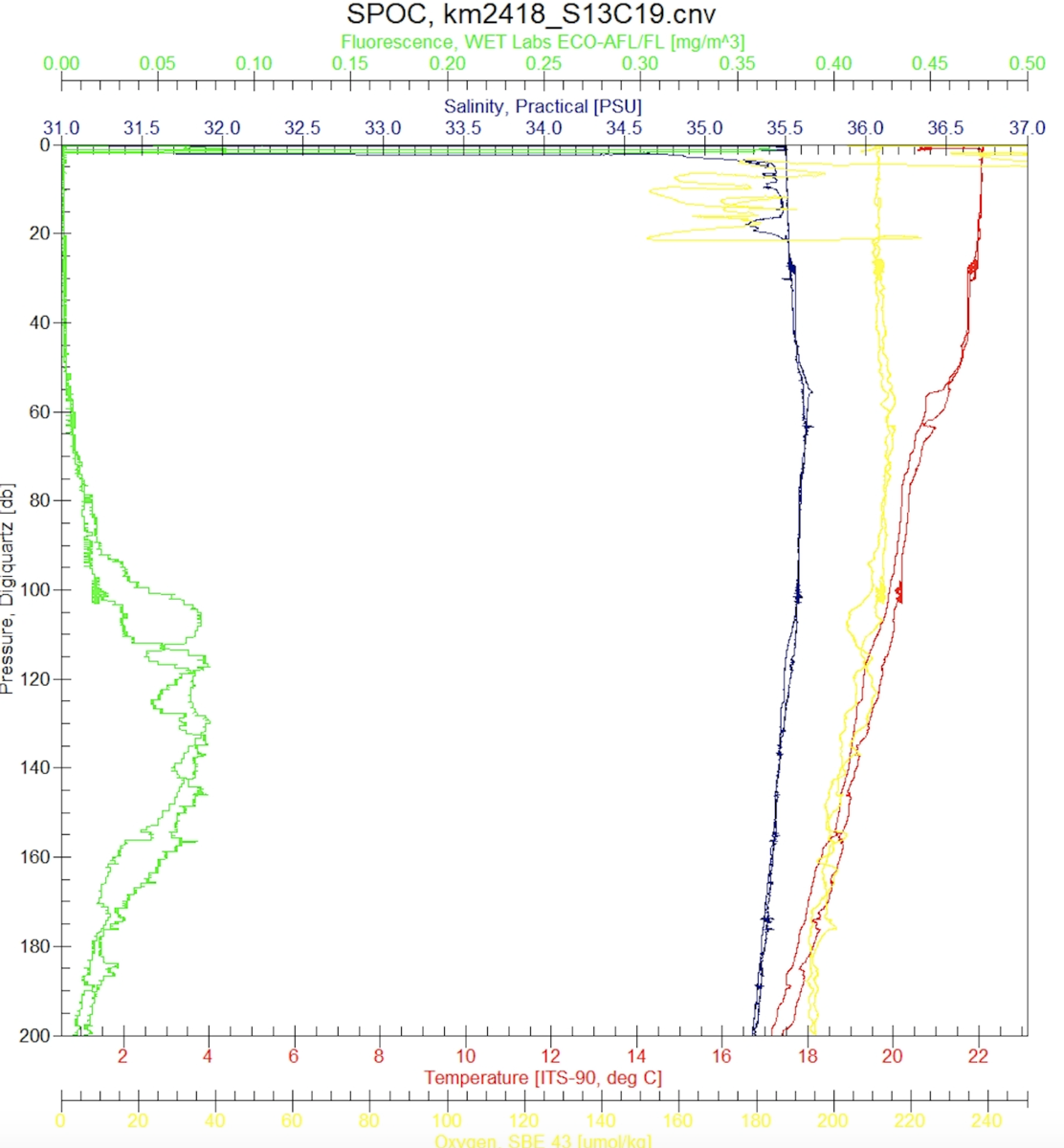

The SPOC team celebrated our last uCTD cast #161 by standing by as Hunter and I tearfully casted our last one. Data wizard Dr. Daniel Murratore promised us to analyze our cast once it was retrieved and they delivered these beautiful graphs! I am so excited to see the paper and the research that will eventually reference this impressive data set, hopefully soon!

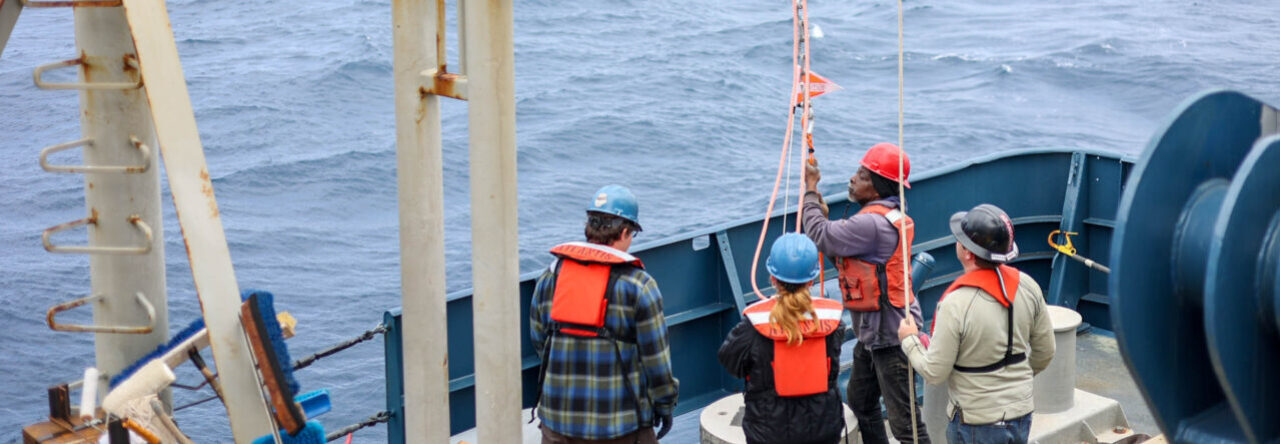

– SPOC Team helping us celebrate our last underway CTD thus concluding a 161 run!

==========================================================

Another major and significant component of our work was the CTD Rosette Cast that took place every 3 hours while at the long stations.

There were 5 long stations, each containing about 19 – 21 CTD casts, culminating in a total of 101 CTD casts! Most cast traveled to 250 meters ~ (820 ft) since the team was mostly interested in surface processes but we did have at least two 1000 meters cast for each long stratton (for diel studies) and a handful of cast that went down to ~3500 meters for calibration purposes.

Running the CTD console was an exciting experience that taught me a bit about double checking your work, keeping cool under pressure, reading water column profiles on the fly and communicating via radio. Running the CTD was a multi step process that typically involved empty niskins, and then caulking them i.e attaching lanyards to the hooks on the CTD Rosette. Once those are attached, you turn to the bottom of the niskin where you attach the lanyard hooks to the bottom of the bottle, opening them in the process. Once the niskins are set up, you take multiple laps around the CTD, making sure that the bottle caps at the top of the nisking which control the pressure at which water leaves the spigot are closed tightly enough. Then you take another lap making sure that all the spigots at the bottom of the nisking are sticking out, so as not to lose samples when you’re moving the CTD back onto the ship. Failure to do all the steps above could result in damage to the rosette or the niskins which should be avoided at all cost.

– Briana Prado caulking CTD bottles

The last lap you take is to take off the caps off the sensors. This CTD rosette was equipped with a UVP, PAR, LIST and syringes on the oxygen sensors, so I’d have to make sure that those were off and ready to collect data. Once the CTD Rosette is set up, I turn back to the lab, collect my cast sheet and relay the information on the cast sheet to the log sheet where I’d take note of starting and ending latitude and longitude, depth of the water column, time the CTD Rosette went in and out of the water, and the depths at which we are firing the bottles. While that is happening, the Ocean Technology Group (OTG) is communicating with the Hawboldt Winch operators about picking up the slack in the wire to get the CTD ready for deployment. Once the slack has tightened, I get ready to turn on the Seabird Deck Box and to start recording on the Seasave software, a software that relays all the live information from the CTD Sensors and rosette back to the ship and the computer you’re working from. Once all that is set up and running, you communicate with the back deck and tell them the package is ready for deployment. The OTG group then checks in with the bridge to get their approval, once warranted, the OTG group checks in with the winch operators to then deploy the package.

Intern: “Back Deck – Lab, the package is ready for deployment.”

OTG: “Roger that lab, Bridge-Back Deck “Can we deploy this package?”

Bridge: “Back Deck- Bridge, You are clear to deploy the package.”

OTG: “Roger that, Winch-Back Deck, Are we clear to deploy the package?

Winch Operators: “Back Deck-Winch, Roger, We are now deploying the package”

Once in the water, we let the CTD soak at the surface, to allow the sensors to equilibrate with the water temperature and start pumping water through the sensors. After about a minute, I radioed the Back Deck to take the CTD to a pressure-depth of 15 deci-bars at 30 meters per minute. It is essential that the package travel at this specific speed as that is how the CTD sensors are turned on.. Once the CTD pumps are on, I communicate again with a back deck OTG person that we are now clear to take the package back to the surface and then to Target depth ~ 250 meters. Once that is done, we are now ready to take our water column profile.

The CTD profile generates right in front of your eyes. It’s always fun to take note of the chlorophyll maximum or the part of the water column, where most of the phytoplankton are hanging out and see how that changes, hour to hour, based on the time of the day, where we are in the ocean and other oceanographic parameters like oligotrophic waters. Other things we keep an eye out for is the Cpmax or the area of the water column with the highest concentration of particles.

Once we reach our desired depth of lets say ~250 m, we are clear to start firing bottles. The winch operator will declare they have reached the desired pressure/depth.

Winch: “Lab-winch we’ve have hit target depth 250 db or 2-5-0 decibars”

Intern: “Winch- lab, next target depth is 125 db or 1-2-5 decibars”

Winch: “Roger that “Next target depth is 125 or 1-2-5 decibars”

We then wait for the winch to call out 125 decibars, which we double confirm by looking at the screen and reading where the CTD tells us it is in the water column. Once we’ve reached the desired depth, I wait 30 seconds to fire the first bottle. This time is allotted to allow for any disturbances in the water column to settle. Once I fire the first bottle any subsequent bottles are fired at 10 second intervals, for the same reason.

Once I’ve fired the bottles I call out to the winch our next target depth and repeat.

Once we’re near the surface, I call out to the back deck and tell them that we are now clear to recover the package and OTG begins checking in with the winch and bridge folk to confirm they are also ready to recover.

Once the package is recovered, I finish jotting down the meteorological data, log the event in the event page and turn off the deck box. It is paramount to turn off the deck box because you don’t want to electrocute anybody when they start releasing the slack on the wire.

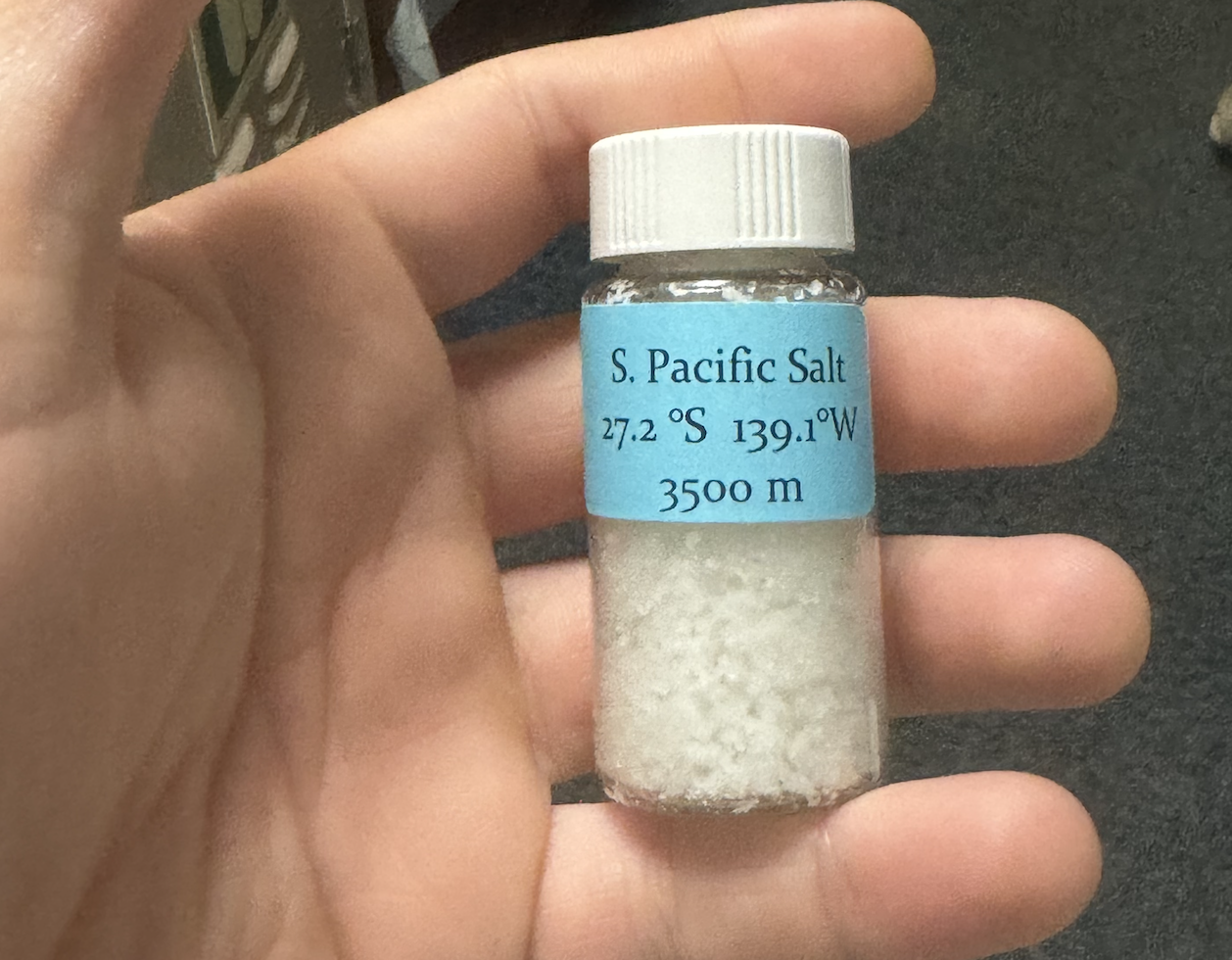

For our last cast, cast #101, we went down to a depth of 3500 meters (~11,480 ft). This cast was used to calibrate the CTD’s oxygen sensors and also collected water from the Antarctic Deep Water water mass. As the name implies, this is water that last saw the surface of the ocean, when it downwelled off the coast of Antarctica. As a result the water is super cold, oxygen rich and salty! Chief Scientist Angelicque White was super cool and boiled down the water to collect and bottle salts for us as a memoir as well as let us cast away a couple pieces of styrofoam to crush them underpressure. We didn’t have too much styrofoam so we had to experiment with different types… some were more succesful than others.

– Before and after pictures of our styrofoam squares that went down to a depth of 3500 meters!

Now that we are done with all the stations, we’ve started to pack up labs. We will be arriving to Tahiti soon, stay tuned!

Cheers,

Briana