Hello Readers! So far on this current cruise, everything has gone great and as I am writing this, we are heading back to port a day early!

But I have to catch you all up to what I have been doing this past week!

My fifth day during this internship was learning quite a few different subjects. I learned more about COAX connections, rope tying, and figuring out a plan to troubleshoot the transmissometer. We did this during transect lines as the transducer needed data, which meant free range on our activities. The first part of the morning we tested the primary antennas and looked at the COAX connections to make sure nothing was corroded. Our tests of connecting and disconnecting cables helped pinpoint which antenna was the culprit and it turned out the side antenna (since there are 3 in a triangle formation) was not working properly. We made a rough plan of what to do the following few days since a scientist on board needs continuous GPS data and had to hold off on that.

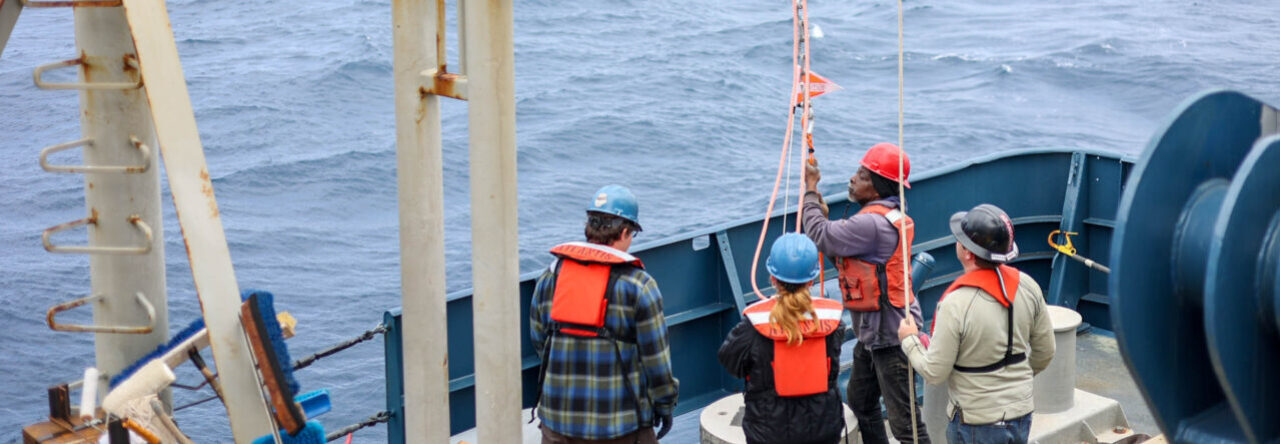

After this event, I went over my rope tying knots, solidified my definition of hitches, and learned a cleat hitch! It will be pretty handy for me when I work more out on the deck when it comes to our next research cruise, a mud cruise as they call it! Basically, we will be taking core samples from the bottom of the seafloor and will be using my cleat hitch skills and tag line skills to help maneuver the coring device, MC-800 Multi-corer Deep Ocean Sediment Sampler, as steady as possible.

We also troubleshooted the transmissometer and had to wait and see if it was fixed in the following few days because we would be arriving to Pensacola port to avoid the wrath of Hurricane Francine! The seas were beginning to get pretty rough, so we made it out of the Gulf of Mexico right on time!

The following day, Grace showed me how to shut down all sampling systems since we would be arriving at port soon and got the okay from the PI. She explained that we have to shut down the systems to avoid sediment from clogging the flow-thru system (since water gets shallow) and the ADCP data at port is irrelevant to the science party. While she showed me how to shut down the systems, she also explained to me what types of data streams through specific software like Seasave and SCS. That also means we have to disassemble and secure the huge transducer pole before going into port. We did just that with a bit of a hiccup, but everything was secure before we moved up into port.

The rest of the day was spent troubleshooting minor issues and once our shift was finished, we hit the town and got to know downtown Pensacola!

On our seventh day, I practiced my rope knots and seemed to forget a few of them. Grace made me do them all until I had them down and that helped me a lot to really drill it into my brain.

Since we were at port and there was clear weather out for a bit, we decided that it would be a good day to create a new cable termination for the suspected antenna. We cut into the antenna and noticed that the inside was completely corroded so we kept cutting until everything looked good and started the termination from there. We used an elbow COAX to start the termination and had to figure out how to solder the very middle inner piece to the COAX connection. After 2 attempts, we figured out how to solder the cable and COAX together and went downstairs to see if the connection works. We saw that the connection worked but that the heading issue was not fixed, and the other antenna was starting to have an issue, so we replaced it with a backup antenna, which seemed to fix the position issues. As for the heading issues, we contacted the team responsible for the software and waited for a response.

Then once our shift ended, we headed into downtown Pensacola one last night before leaving the following morning!

On my eighth day, we started things off slow since we had to secure the transducer pole back on deck before going out to our first station. We couldn’t start our sampling systems until we were out of the bay to avoid irrelevant data and clogging our flow-thru.

In the meantime, we got a response from the team responsible for the GPS software and saw that heading was back up and working!! The heading issue was happening the entire time I have been on the Pt. Sur so having this issue resolved after many troubleshooting attempts was super satisfying and a check off our long to due list.

During the downtime between leaving the bay and reaching our first station, I learned how to start the sampling systems for the ADCP, SCS, flow-thru, and Wi-Fi. There is a bit of a learning curve to understand how to turn on the ADCP and SCS system but with Grace’s help I was able to do it!

Once that was done, I learned how to make ethernet cables which was super fun to me because I have always seen and used them but never knew you could make some yourself! Grace taught me how to make them and how to test the connectivity and realized just how fun it is. I made a few throughout the day with some down time and slowly got better at it!

I also learned how to splice rope, specifically manila rope! Manila is made out of hemp and is pretty rough to work with but if rope falls off the boat, its biodegradable. However, since it is biodegradable, if it gets saltwater on it, it will degrade much faster compared to other materials of rope. The different splicing techniques I learned are back splice, end to end splice, and eye splice. I also learned how to do whipping knots to secure the base and end of my ropes, to make sure its super secure.

On my ninth day, we continued troubleshooting the transmissometer by replacing the ports with the transmissometer and PAR sensor. We originally were using a y-cable so that the fluorometer and transmissometer were sharing a single port but, to rule out any issues in case the pins on the CTD were the issue, I switched the ports with the PAR sensor. This meant that I used a y-cable to share the PAR sensor and transmissometer on the PAR port, meaning the fluorometer will get its own cable and port.

After I was done switching cables, Grace taught me how to splice rope with synthetic material! Synthetic rope doesn’t degrade as easily as organic material, but it frays easily. Working with this type of rope was hard to tuck in on itself but I was eventually able to complete the splice knots.

Grace also taught me a new special knot called a shrimpers bag knot! Basically, when you make an overhand knot around a bag and make continuous repetitive knots that make a long-braided line, you yank it to catch whatever you want (called shrimpers bag for a reason). It was relatively easy to tie and convenient for various reasons.

Later in the afternoon, Grace requested two ethernet cables from me since she has had issues connecting her computer system to the ADCP monitor, so I went to work! When it comes to troubleshooting, Grace likes to replace cables or create new cable terminations for them first before moving onto the deck box or device and then eventually the software, that way it’s easier and less complex to figure out the issue. I quickly made her two ethernet cables and replaced them on the ADCP deck box and she tried testing it, but nothing changed. I tested the ethernet cables for connectivity earlier and they were working perfectly fine, so we know it is not the cable that is the issue. She thinks it might be a software issue, but it isn’t too much of an problem at the moment.

The following morning, we continued to troubleshoot the transmissometer and decided that we would switch the instrument with another one we had on previously just to see what would happen. We were aware that the previous transmissometer was giving just as bad data as the current one, but we thought that the cable and port switch might do the trick for the previous one. I went ahead and switched the transmissometers and calibrated it and made a new configuration file for it! I did this all on my own and was surprised by myself at how quickly I grasped things on the software side of the CTD instruments!

Later that afternoon, Grace instructed me to take a look at the backup GPSs (BX982) and see how the connections are looking like. I went up above the wheelhouse to take a look at the cables and saw that there was some corrosion beginning to form on the inside of the COAX cables and a lot of corrosion on the outside of the antenna. To troubleshoot, Grace said I should just clean the inside of the COAX cable and the outside of antenna with electronic cleaning liquid. After cleaning the cables and antenna, we tested to see if the backup GPSs were giving heading and position now but there were still errors. The next best thing would be to make new COAX cable terminations for the backup antennas, and we waited until after lunch to do so!

After lunch, Grace gave me the opportunity to do the cable stripping, termination, and soldering all on my own, which I was a bit hesitant to take on but did so anyway. How else am I supposed to learn if I don’t make mistakes and improve from there? I got all the supplies I needed to make new COAX terminations and went up to fix the GPSs. I went straight to stripping wire and found a lot of corrosion inside both of the cables. Later, Grace joined me and looked inside the old COAX connection I had already cut off and she found huge amounts of corrosion inside the connection which was our culprit in our errors. Once I was done stripping both cables, I went to solder the COAX elbow connection and cable connection conductor together, which in all honesty, was the most intimidating part of it all and took me a while so I can avoid big mistakes. I didn’t solder a good connection at first but after a few tries I eventually got the two pieces soldered together and used heat shrink to really secure the cable and COAX cable together. We finally put the cable back into the antenna and tested to see if it was working, and it was! The best part is that after a few hours, for the GPSs to reconfigure on their own, they finally got position and heading on our feed! YAY! We fixed all the GPSs onboard right on time before our upcoming mud cruise!

It was another intense but successful week of troubleshooting, learning, and practicing patience. See you all next week!

Kristine