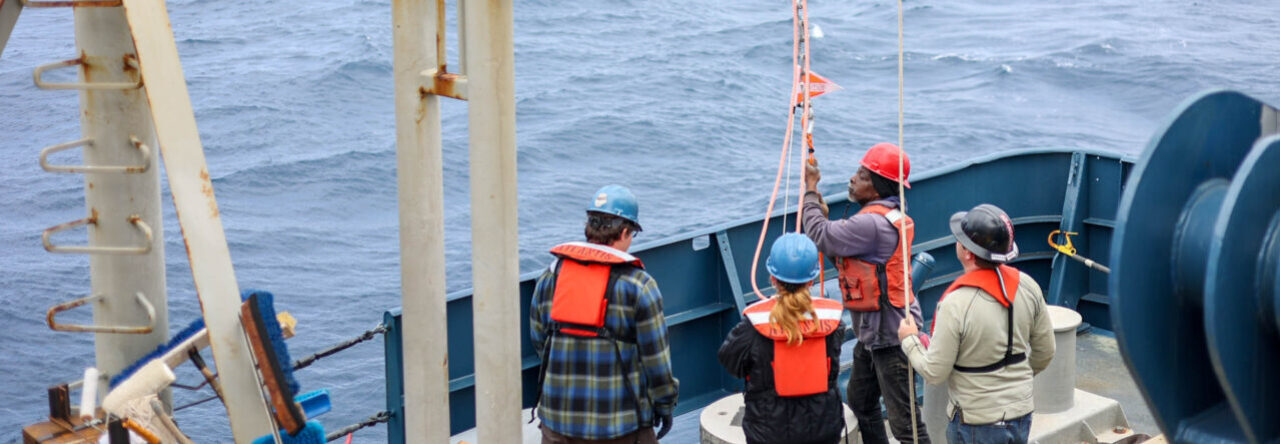

Hello! All is well on the Langseth; I’ve really enjoyed working with Cody (the Chief Science Officer), the other interns, and the rest of the crew so far. Quick update—we are no longer headed to Costa Rica. Things have been a little crazy around here, and because of some uncertainties about funding we’ve made a rare last minute change in plans. We are now headed to Cape Verde to pick up some OBS equipment that was deposited last year, which means we’re sailing across the Atlantic!

This first week has been super eventful and I’ve learned a lot. The Langseth is a very impressive boat and it’s been really great getting my bearings around the ship. It’s a global-class marine seismological vessel—the only of its kind in the UNOLS fleet—and the equipment they have on board is incredible. We’ll start working more closely with some of those systems next week—most of what we’ve done so far has involved a lot of maintenance and upkeep across the ship’s different labs and stations. We’ve packaged and shipped some outdated equipment back to Columbia and WHOI, and have also unpacked and stored new shipments of PPE, tools, and stores. Some daily and weekly responsibilities we have include cleaning the labs and making sure all loose items are tightly secured for the transit. It’s been quite busy but I’ve enjoyed getting my hands dirty, especially on a few key projects!

One of our first projects involved prepping the Lamont-Doherty Earth Observatory’s gravimeter for transport back to Columbia. This instrument is incredible—it’s a gray box built in the 60s that measures localized gravitational pull. It’s fragile and a little finicky, so we learned how to run daily checks on the instrumentation, run a gravity-tie test for calibration, and how to prepare it for transport without ruining everyone’s day (it would be a very costly break). We had to constantly keep it hooked up to a power supply and had to be very careful while moving it so as not to upset any of its internal workings. I’m very grateful I got the chance to work with it and to pick Cody’s brain about what makes it tick.

Another one of our projects was creating two shelfs/desks in the Dry Lab to create more workable surface area. I’ve never worked seriously with power tools before, and it was a blast getting to test things out with all the equipment and materials around the ship. This was definitely the project that took us the longest: we had to plan out the dimensions, clear the location, figure out our materials, cut out our metal frame, cut out our wooden surfaces, bolt pieces together, smooth out rough patches, and stain the wood. I’m very proud of our end product and it’ll definitely inspire me to work on more construction projects once I get home.

Finally, we spent some time on the workboat when we went to go get it fueled. This boat is kept on the ship in the event technicians need to perform maintenance on deployed equipment or lines. We were only supposed to be gone for an hour and a half, with the fuel dock being about 5 miles away, but our little vacation turned into a 4 hour maintenance trip. We initially had some problems with our electronics and port motor, which snowballed into an oil leak we had to patch and refill at the dock. It was a great time! We saw some dolphins, enjoyed the weather, and got very, very familiar with the inner workings of outboard motors.

Really looking forward to starting the transit tomorrow! I’m excited to get the ball rolling with a bit more technical projects, including working on our digibirds, getting familiar with our sonar systems, and testing out the streamers. Fingers crossed that I don’t get seasick!